Custom Spray Booths and

Finishing Systems

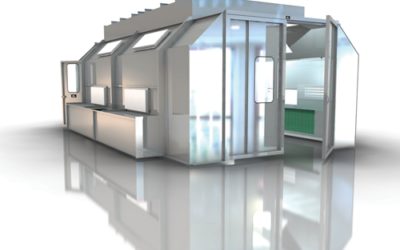

Paint Booths

Powder Booths

Exhaust Chambers

Mixing Rooms

Prep Stations

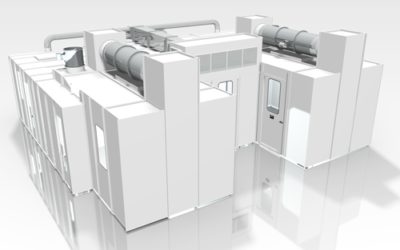

Engineering Beyond the Booth

With over 40 years of experience under our belts, we’ve learned that the perfect custom spray booth or spray finishing system is more than just a piece of industrial equipment. It’s an integral part of a manufacturer’s mission to make the best possible products with max efficiency.

That’s why we work closely with our customers to learn how they work, what their vision is for the future, and how we can help get them there.

Take the First Step

No matter the scope of your project or the challenges it may present, our spray booth advisors are standing by to help you build the perfect solution.

Custom Paint Booth Designs

Mick’s Paint

Spray Systems understood, because of the nature of our business, that our new spray booth required custom considerations. As an educational institution, the booth design and engineering for Dixie Technical College included particularly unique...

Dixie Technical College

Spray Systems understood, because of the nature of our business, that our new spray booth required custom considerations. As an educational institution, the booth design and engineering for Dixie Technical College included particularly unique...

Precision Body & Paint

Precision Body and Paint, a customer in Bend, Oregon, specifically chose Spray Systems to engineer a custom-built spray enclosure that could operate efficiently under the cold conditions of their winters, while still providing a high-end...

Walla Walla Foundry

The Walla Walla Foundry is an internationally known modern contemporary bronze casting facility. The Foundry provides a range of services for producing contemporary sculpture. We’ve completed two booth projects and Spray Systems Inc. provided...

Fender Music Instruments

Fender Music Instruments Corp. selected Spray Systems to design and install a custom paint spray booth for their Robotic Paint Spray system. Because of our reputation throughout the industry, integrators and other booth installers recommend us to...

Puckett Machinery

There are dozens of projects that could illustrate our capability and commitment, but our recent custom installation for Puckett Machinery is a perfect example. As an authorized dealer handling sales, rentals and maintenance of heavy equipment, this...

Amada America

Amada America, a worldwide manufacturer of the finest CNC and heavy equipment machinery chose Spray Systems for their custom paint booth...

Air Tractor, Inc.

Initially, we had planned to upgrade the oldest of nine spray facilities. But we came to appreciate that the better and more cost-effective solution was to create a custom booth to fit the existing infrastructure....

Spray Systems News & Info

Your Guide To: Selecting the Right Filters for Your Paint Spray Booth

The primary benefit and feature of any spray paint booth is its ability to contain toxins so that they can be disposed of in a safe, responsible manner. Filters are the mechanism that bears the brunt of this responsibility, which makes them one of...

Water Wash vs Dry Filter Spray Booths: Your Selection Guide for Industrial Applications

Direction of airflow is not the only primary consideration that manufacturers must account for when selecting a spray paint booth for their...

How to Buy a New Spray Booth: Our Sales Process

There’s a big difference between a product and a solution, and at Spray Systems, we’re committed to providing innovative engineering, expert booth design and a customer-centered advisory process to ensure your booth investment delivers the...

Recovery vs. Non-Recovery Powder Booths

Operators who rely on powder coatings for their finishes have several important decisions to make when buying their spray booths. One of the biggest, and often most confusing one, is the choice between a “recovery” and...

A Guide to Protecting Your Spray Booth Through Every Season

Every kind of spray and finish application has an ideal temperature and humidity range based on the specific process and compounds involved. Learn how to protect your spray...

Spray Booth Lighting: A Guide to Finish Quality, Safety and Operational Costs

Making sure that your spray booth is properly lit can mean the difference between a good finish and a great finish. Read more about paint booth lighting...

How to Prep Your Spray Booth in the Case of a Fire

Fire is among the most serious potential hazards associated with spray and finish applications, even those conducted in a fully-maintained and compliant spray booth. There are many different ways to limit this risk, but business leaders also need to...

Common Appearance Issues in Liquid and Powder Coating

There's little room for error when coating, especially in industries with strict quality standards. Here's some common causes in coating appearance...

Have Questions?

Get in touch with a personal Spray Booth Specialist for expert advice and custom solutions that serve your needs.