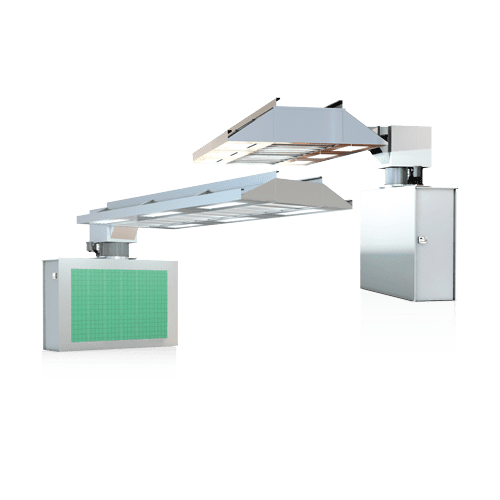

Downdraft Paint Prep Stations

For high-volume manufacturers, prep stations for spray finishing booths are the perfect way to increase productivity while improving the quality of your finishing process. By isolating processes like masking, stripping, and sanding to a separate prep station, you avoid further contaminating finishing areas while increasing the efficiency of your preparation process. Additionally, prep stations for paint spray booths typically require far less airflow than a paint booth itself, which means fewer energy costs and less overhead. Contact us to learn more about the downdraft paint prep stations.

Choosing the Right Paint Prep Station

Semi-Downdraft vs. Full-Downdraft Prep Stations

Semi-Downdraft

“Downdraft” refers to air travel and its direction within the paint prep station. By design, a downward airflow will be maintained starting at the supply filters in the ceiling of the prep station down to the floor level. Our semi-downdraft paint prep station draws exhaust air into the filters at the base of the cabinet and provides the added advantage of not requiring a pit while still maintaining downdraft airflow.

Full-Downdraft

Similar to our semi-downdraft model, our full-downdraft paint prep station uses uniform downward airflow to pull contaminants into a floor-level grating. While a full-downdraft paint prep station requires a below-grade pit installation, it is more effective at containing all dust particles than a semi-downdraft model.