Fender Music Instruments Corp. selected Spray Systems to design and install a custom paint spray booth for their Robotic Paint Spray system. Because of our reputation throughout the industry, integrators and other booth installers recommend us to their customers. Though Fender’s space was confined, we were able to make two automated conveyor booths connecting to a flash room and our engineers were able to incorporate all of Fender’s requirements. They’re able to work faster due to these custom built airbrush spray booths.

“The booth was built with such precision that the construction time to assemble was just two days. I can tell you from experience that after the booth was installed and running, we made the right choice – Spray Systems made my job easy. At Fender, we pride ourselves on the quality and attention to details to deliver the best instruments we can make. After working with Spray Systems, we can see they share the same passion.” — Bill Holmes, Facilities Manager, Fender

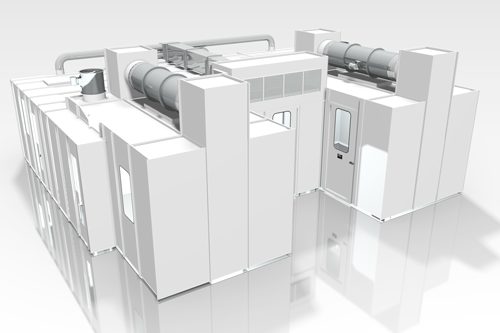

Automatic & Conveyor Manufacturing

Automated/conveyor finishing operations bring about a unique set of challenges for manufacturers when choosing the right spray booth – all must be considered coming up with a spray booth design for automatic and conveyor manufacturing. From simple overhead conveyor loops, to more complicated power-and-free conveyor systems, or high-production palletized floor conveyorized lines, Spray Systems can design the right spray booth to meet your automated requirements.