Industrial Manufacturing Spray Booths

Industrial Manufacturing Solutions

Industrial product manufacturers face a number of spray environment challenges that are specific to their industry. From spray-coating golf balls to painting industrial parts, an industrial spray booth must address the unique production needs of a manufacturer’s individual finishing processes. Because of this, there’s no one-size-fits-all solution for industrial finishing.

That’s why Spray Systems takes time to understand every aspect of our customer’s production process. We listen and take note of the things that matter: facility dimensions, production capabilities, and what a customer’s ideal production rate looks like. At Spray Systems, we do more than just build manufacturing spray booths, we engineer powerful products and finishing equipment for the industrial manufacturing industry that transform our customers into the powerhouses they were meant to be.

Industrial Spray Booth Products

Challenge Accepted

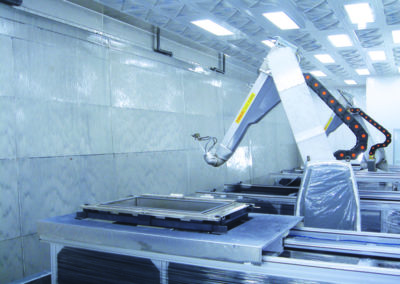

Automatic and Conveyor Manufacturing

Safe and Efficient Booth Design

Products

Bench Spray Paint Booths

Our bench booth is a perfect industrial paint booth solution for small parts finishing. Designed to achieve balanced airflow while removing particle debris, our bench booths are an effective way to boost production capabilities through increased efficiency.

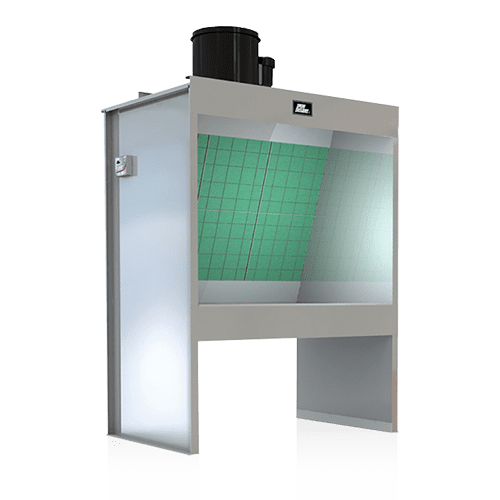

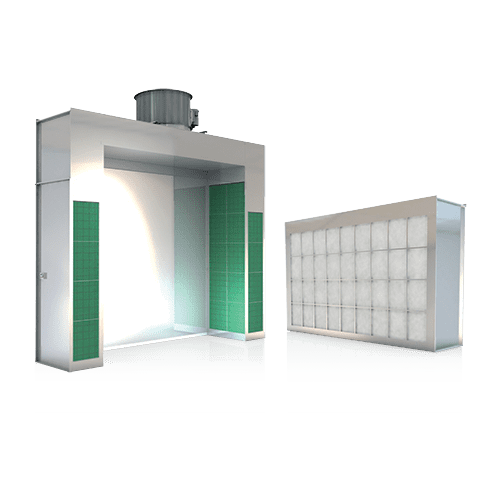

Dry Filter Spray Booths

Engineered for flexibility, our modular open-face designs ensure the highest quality finish for any production process. By utilizing a crossdraft airflow, our industrial paint booth products efficiently remove paint overspray that can impact finishing quality.

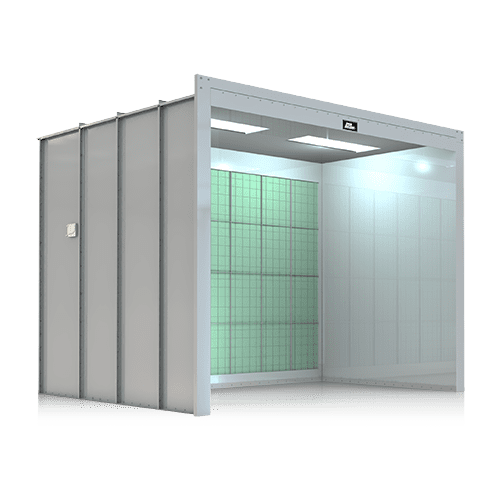

Industrial Drying Enclosures

With the help of our industrial manufacturing drying enclosures, you can increase productivity and accelerate the drying time of water-borne and solvent-based coatings. By accelerating the drying time, operators can achieve optimum curing and an overall higher quality finish.

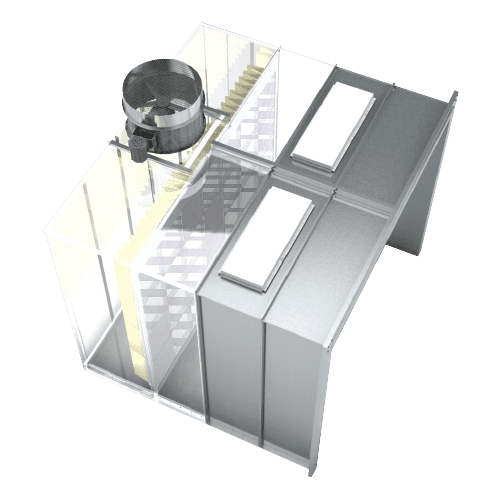

Exhaust & Supply Chambers

Exhaust and supply chambers are great for converting part of your facility for spray painting. Our modular designs mean that they can also be used as an effective preparation area for sanding or cleaning parts prior to paint finishing.

Recovery Powder Booths

Ideal for a heavy-production powder usage, our cartridge recovery powder booth provides a powerful industrial paint booth environment. These booths are designed with a cartridge-style filtration system that captures powder overspray, allowing clean air to recirculate back into your plant without affecting the rate of production.

Non-Recovery Powder Booths

Through our three-stage filter system, our non-recovery powder booths provide an extremely effective method of powder collecting at half the cost of a traditional cartridge collector-type powder booth. Because of the specific exhaust system, we recommend non-recovery powder booths for “spray-to-waste” batch operations.

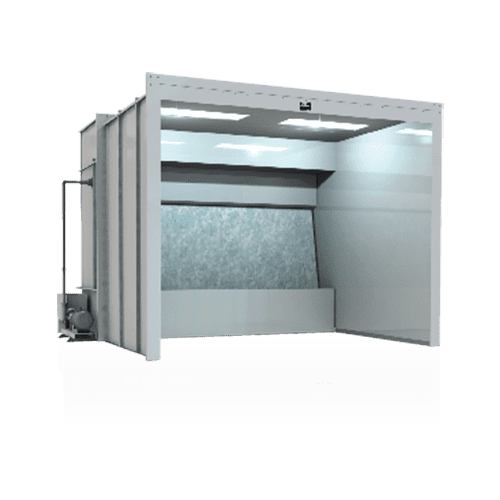

Water Wash Spray Booths

Our water wash booths are best utilized for high-volume paint usage and are extremely effective at removing paint particles from the exhausted air. Compared to dry filter booths, water wash booths can filter a wider range of paints and are generally favored by all health, fire and building codes.

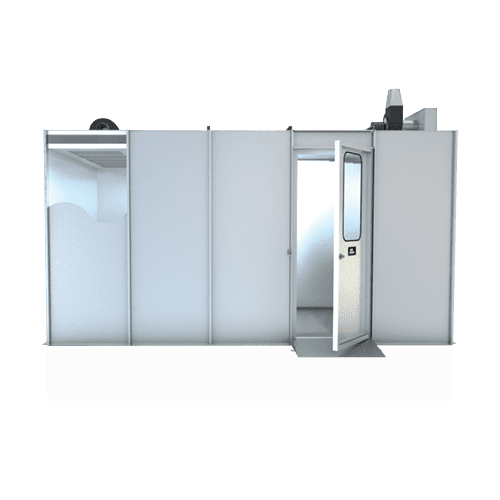

Mix Rooms

To ensure the best quality finish, operators need a clean, well-ventilated and illuminated area for mixing and preparing the perfect color match. Our modular mix rooms can function stand-alone or fixed to an existing industrial paint booth, and are designed to achieve a perfectly balanced airflow while removing detrimental debris particles.

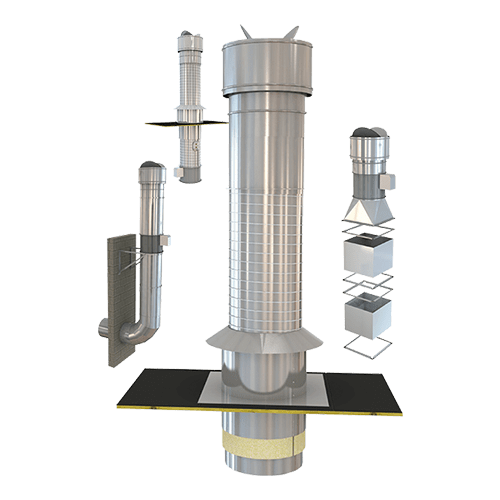

Exhaust Ducts

Ventilation is arguably the most important aspect of any industrial paint booth, which is why we offer a wide selection of square, round and spiral exhaust components. Additionally, we offer custom exhaust designs based on your facility’s unique needs.

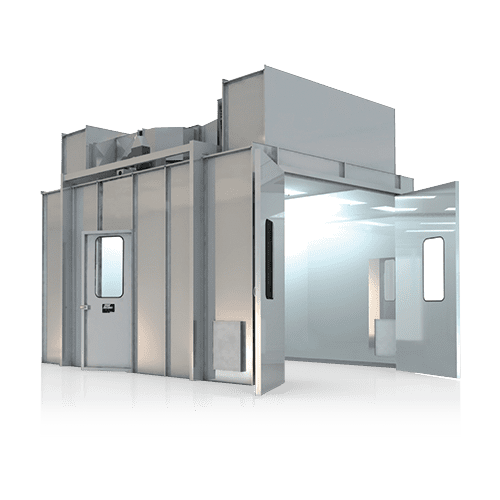

Custom Industrial Spray Booths

Fender Musical Instruments Corporation

Fender Musical Instruments Corp., a globally-recognized music equipment manufacturer, selected Spray Systems to design and install an industrial spray booth for their robotic paint spray system. Though space was confined, we were able to construct two automated conveyor booths connecting to a flash room, saving Fender time and money in production finishing costs.

Walla Walla Foundry

Walla Walla Foundry, an internationally-recognized modern contemporary bronze casting facility, partnered with Spray Systems to design two custom industrial spray booths. The two booths, a pressurized crossdraft booth and a downdraft booth, were designed to fit in a compact 20-foot space. Since installation, Walla Walla Foundry has reported reduced overhead and increased production rate.

Our Industrial Manufacturing Customers

Have Questions?

Get in touch with a personal Spray Booth Specialist for expert advice and custom solutions that serve your needs.