Engineering Beyond the Booth. Proven and Trusted for More than 40 Years.

Case Studies

Aerospace Case Studies

Initially, we had planned to upgrade the oldest of nine spray facilities. But we came to appreciate that the better and more cost-effective solution was to create a custom booth to fit the existing infrastructure.

Jet Propulsion Laboratories (JPL) awarded Spray Systems for its high profile, space-flight component group. JPL imposed critical challenges for Spray Systems when they asked Spray Systems to provide the most effective spray environment for its components while meeting stiff local, state, and federal air quality regulations

Industrial Manufacturing Case Studies

The Walla Walla Foundry is an internationally known modern contemporary bronze casting facility. The Foundry provides a range of services for producing contemporary sculpture. We’ve completed two booth projects and Spray Systems Inc. provided precisely what we ordered.

Fender Music Instruments Corp. selected Spray Systems to design and install a custom paint spray booth for their Robotic Paint Spray system. Because of our reputation throughout the industry, integrators and other booth installers recommend us to their customers.

Large Equipment Case Studies

There are dozens of projects that could illustrate our capability and commitment, but our recent custom installation for Puckett Machinery is a perfect example. As an authorized dealer handling sales, rentals and maintenance of heavy equipment, this customer expected a booth solution that could accommodate components and vehicles of varying size.

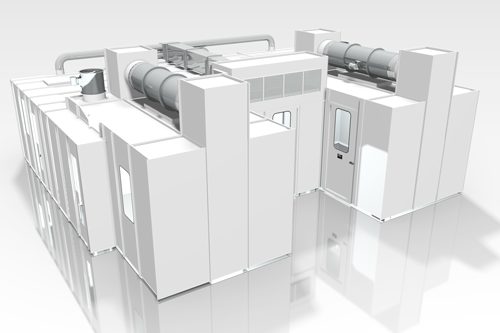

Amada America, a worldwide manufacturer of the finest CNC and heavy equipment machinery chose Spray Systems for their custom paint booth design.

Automotive

Spray Systems understood, because of the nature of our business, that our new spray booth required custom considerations. As an educational institution, the booth design and engineering for Dixie Technical College included particularly unique specifications in order to satisfy curriculum requirements and to fit in aesthetically.

Spray Systems understood, because of the nature of our business, that our new spray booth required custom considerations. As an educational institution, the booth design and engineering for Dixie Technical College included particularly unique specifications in order to satisfy curriculum requirements and to fit in aesthetically.

Precision Body and Paint, a customer in Bend, Oregon, specifically chose Spray Systems to engineer a custom-built spray enclosure that could operate efficiently under the cold conditions of their winters, while still providing a high-end finish.