Spray Booth Airflow & Ventilation Design

Spray booth airflow design is an important element of any spray booth, so it’s one of the first things finishing operators need to consider when upgrading to a new booth.

While there are only a handful of options when selecting a type of booth, each one carries a unique set of advantages and possible drawbacks. Spray booth ventilation design impacts every aspect of a booth’s operation, so companies should carefully weigh how their chosen airflow design will affect operating costs, quality of results, and workplace safety.

Airflow Designs

Crossdraft

Downdraft

Semi-Downdraft

Modified Downdraft

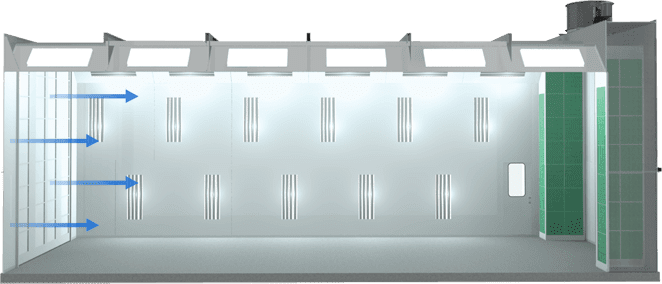

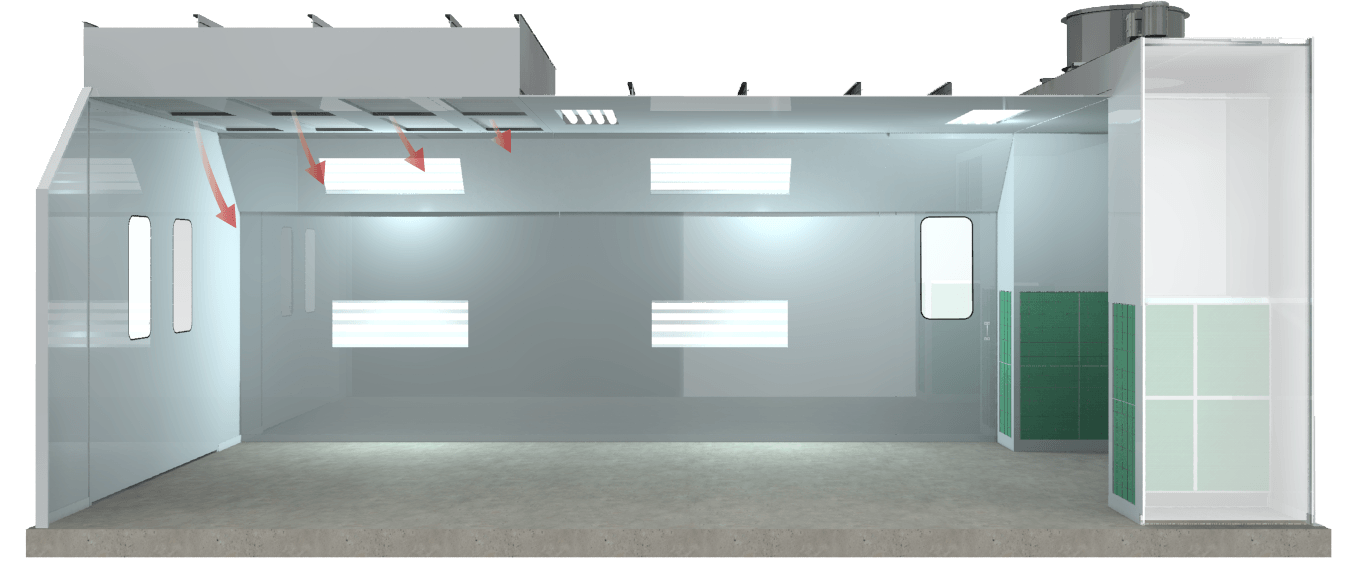

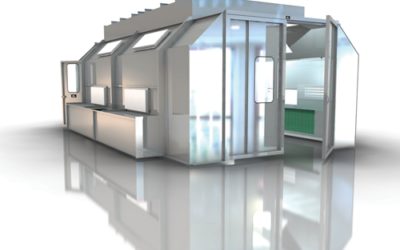

Crossdraft Airflow Designs

Recommended for:

All Industries + Basic Finishing Requirements

- Cost-Efficient Performance

- Minimal Installation Requirements

- Simple Maintenance and Upkeep

The standard in airflow designs, a crossdraft spray booth can be designed to handle a wide variety of uses and is typically recommended for parts that require a basic finishing quality and application process. The minimal installation requirements needed for this style of airflow design make it an ideal solution for most finishing facilities. The term crossdraft refers to how the air travels through the booth: horizontally along the “cross-section” of the booth.

Stage 1

Air enters through the front of the booth and then through the intake filters. As the air passes through the filters contaminants are captured. This is accomplished without sacrificing the quality or volume of the airflow itself.

Stage 2

Horizontal airflow intake causes air to flow uniformly over painted parts and through a rear exhaust chamber. The exhaust chamber incorporates exhaust filters so that the air can be filtered from any paint overspray as it passes through the chamber.

Stage 3

As air passes through the exhaust filter, it is pressed through a continuous filament glass fiber with an open weave pattern. This airflow design prevents face-loading and fogging by changing the direction of paint-laden air throughout filtration. The clean, filtered air now continues through the exhaust plenum, which is designed to balance airflow throughout the entire booth.

Downdraft Airflow Designs

Recommended for:

Aerospace and Automotive + High-Quality Finishing Requirements

- Powerful Performance

- Pit Installation Requirements

- Moderate Maintenance and Upkeep

Like crossdraft airflow designs, a spray booth with downdraft airflow can accommodate a wide variety of parts and uses. However, downdraft spray booths are typically recommended for parts that require a higher quality finish. Notably, conventional downdraft airflow designs require a below-ground pit for proper operation, which creates additional installation concerns. The term downdraft refers to the direction of airflow in a downward movement from the ceiling down towards the floor of the booth.

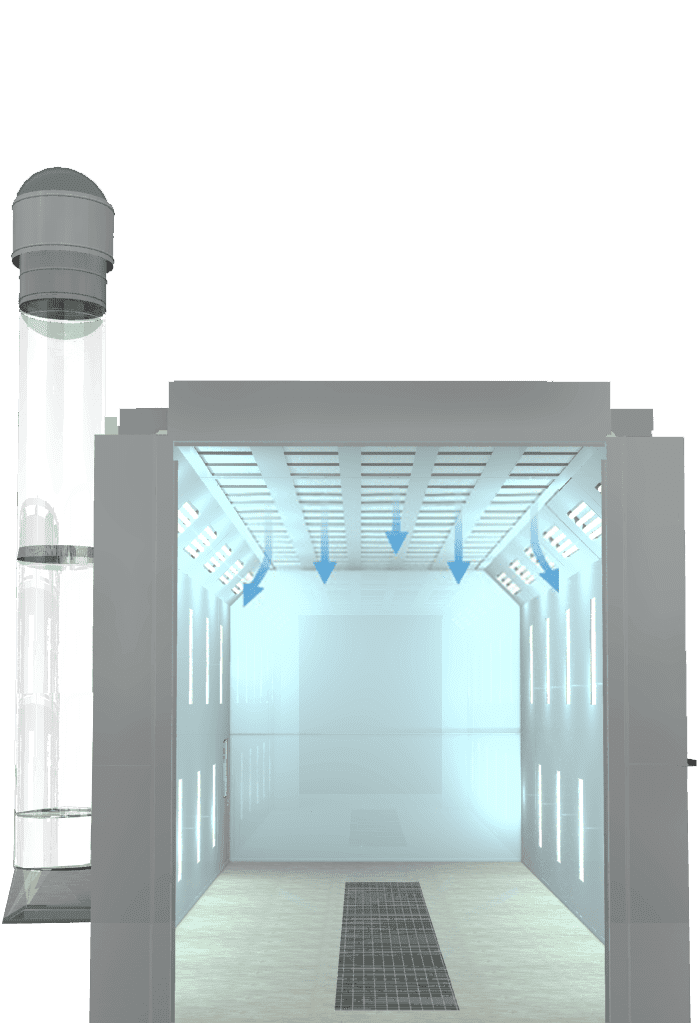

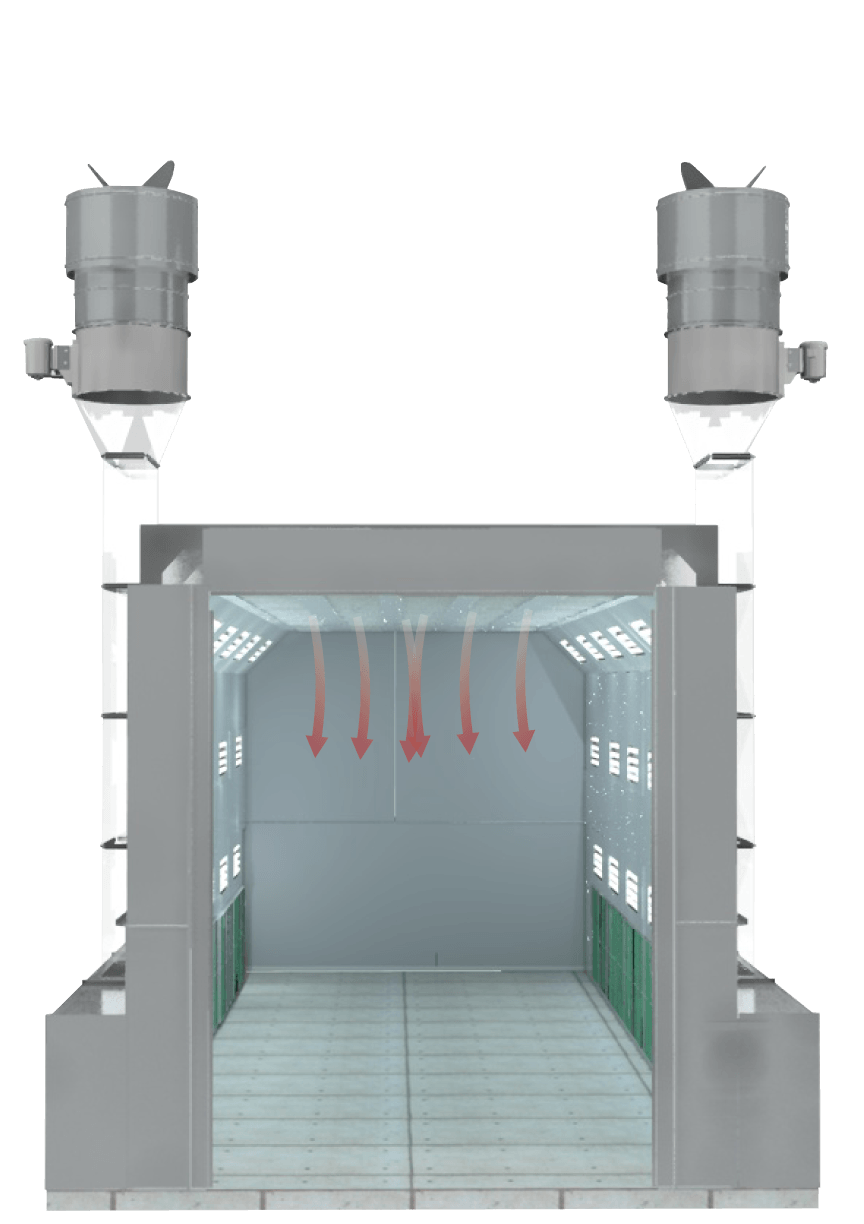

Stage 1

Airflow is introduced into the booth’s air supply plenum and drawn through the supply filters located in the ceiling, which acts as a diffusion media. The multiple synthetic layers of filtration are the result of combining a pre-filter, which consists of a high-performance cover mat, with a final filter of progressively structured media, which is thermally bonded and treated with a special adhesive tackifier.

Stage 2

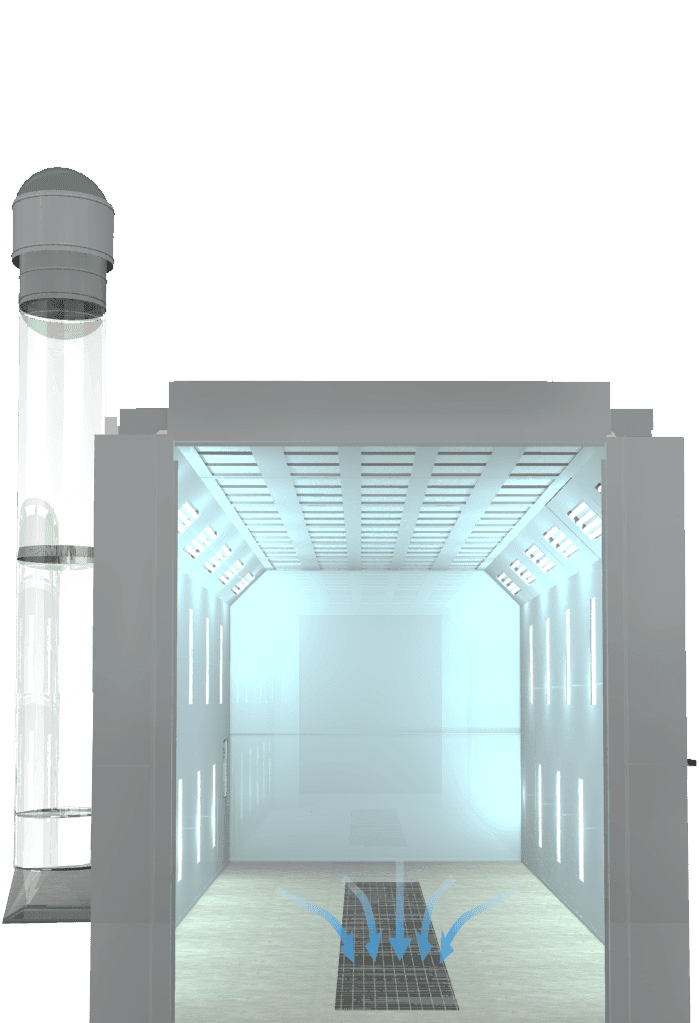

The clean air continues down and around the part, collecting overspray along the way. This overspray is then pulled downwards through exhaust filters located in a grated pit at floor level. As air passes through the exhaust filter, it is pressed through a continuous filament glass fiber with an open weave pattern for maximum efficiency.

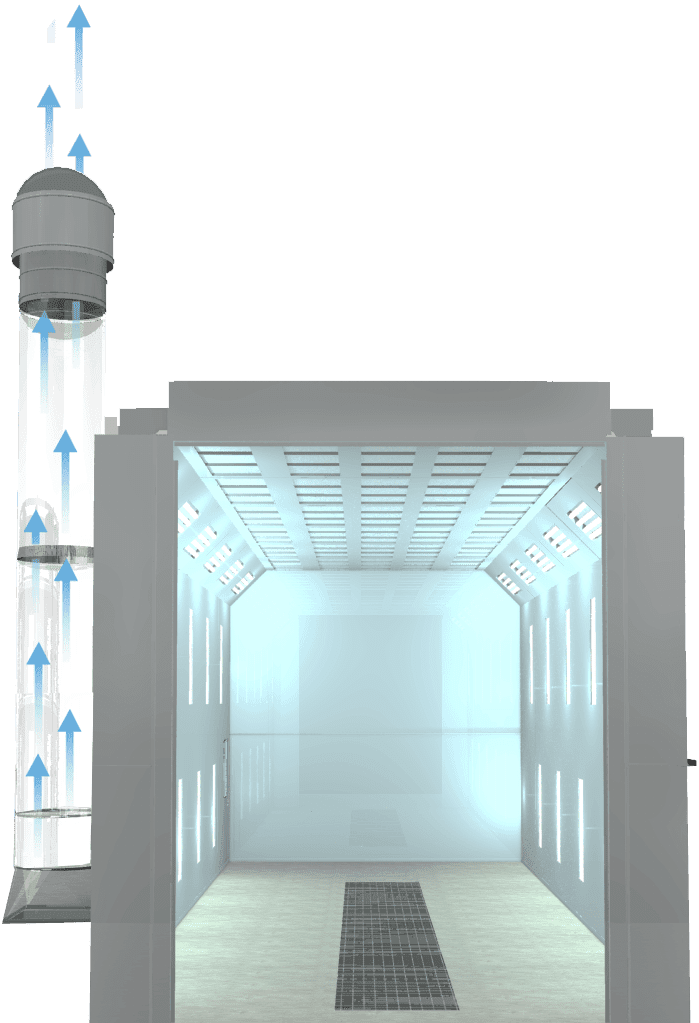

Stage 3

To prevent face-loading and fogging, paint-laden air is forced to change direction many times as it passes through the filtration system. Once in the filtration system, it passes through an exhaust fan designed specifically to accommodate the static pressure of the exhaust filters. Spray Systems precisely matches the size of the motor and fan performance for each booth, so that each fan operates at dBa levels well below OSHA limits.

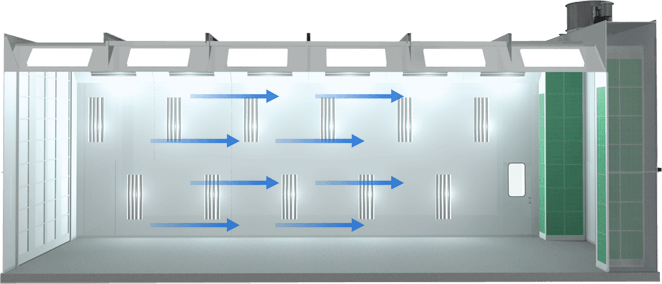

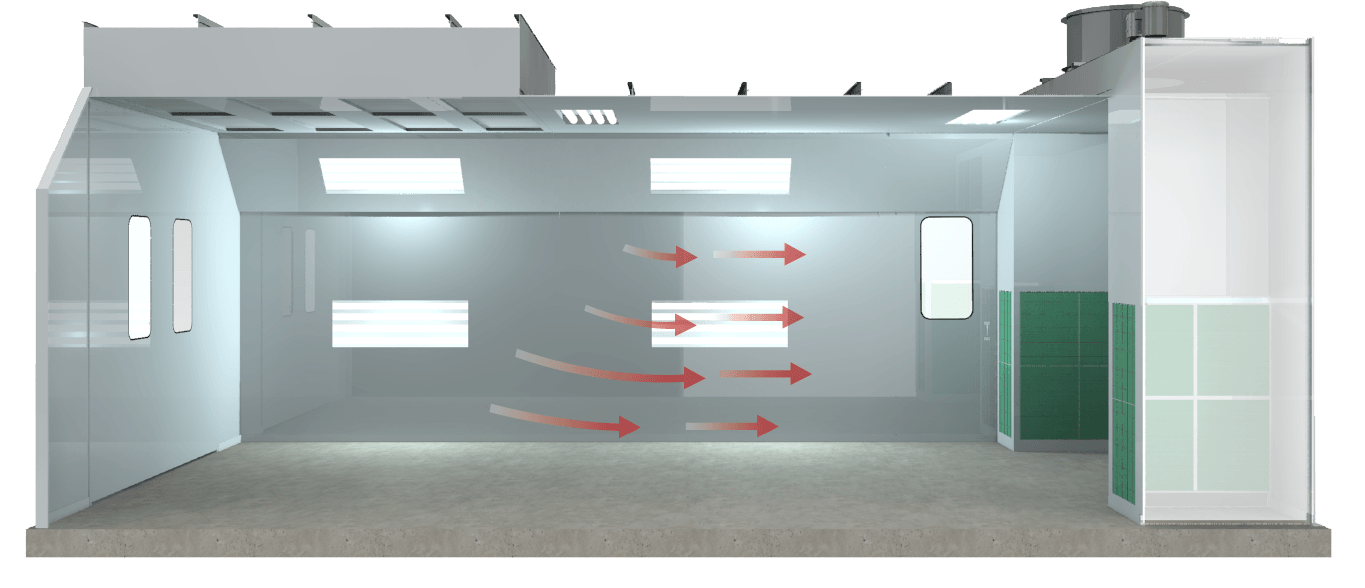

Semi-Downdraft Airflow Designs

Recommended for:

Aerospace, Automotive, and Large Equipment + Complex Finishing Requirements

- Balanced Performance

- Minimal Installation Requirements

- Simple Maintenance and Upkeep

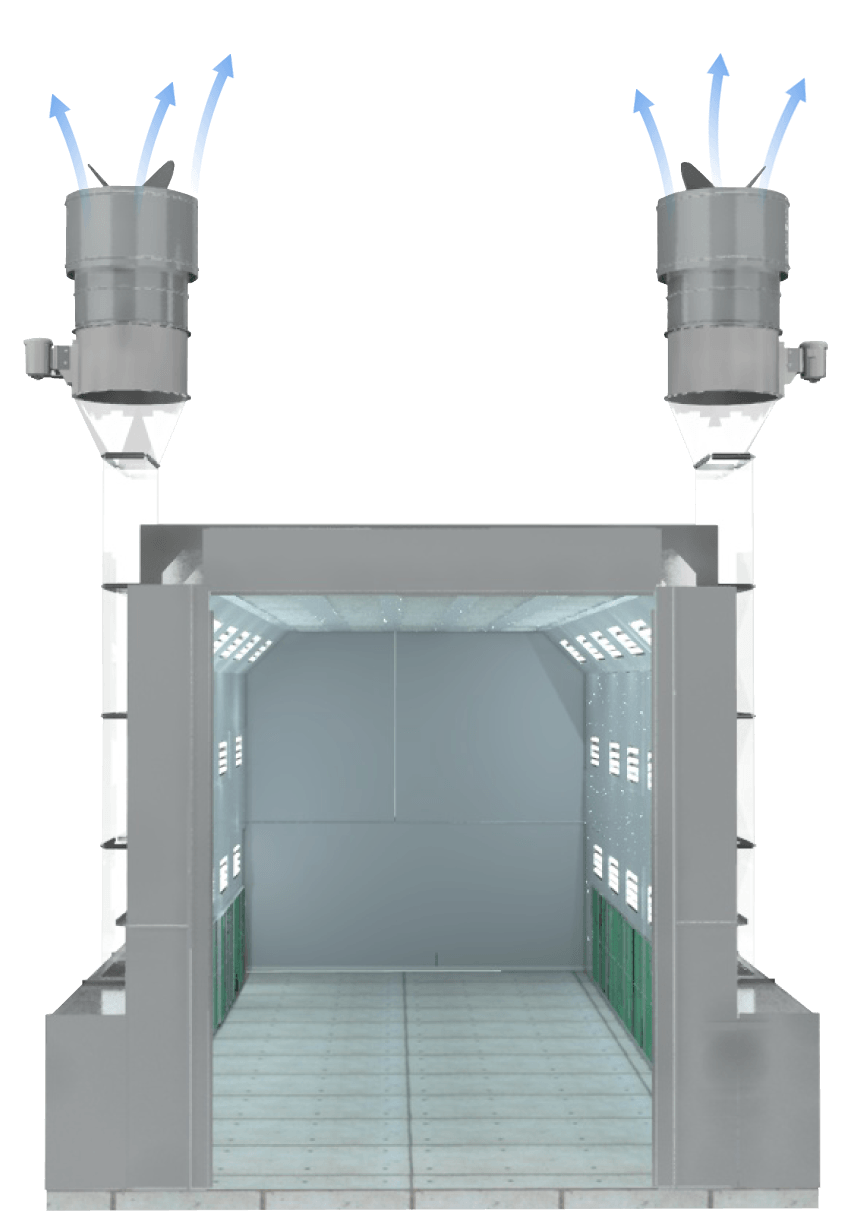

Stage 1

Air is drawn through the top of the booth via a ceiling supply plenum and passes through intake filtration comprised of multiple synthetic layers. This ensures that clean air is introduced into the system while providing uniform airflow throughout the booth.

Stage 2

As air passes through the booth and towards the exhaust filters, uniform airflow collects overspray around the finishing product and moves particulate away from the spray environment. These exhaust filters utilize a continuous filament glass fiber with an open weave pattern to further prevent face-loading via saturation.

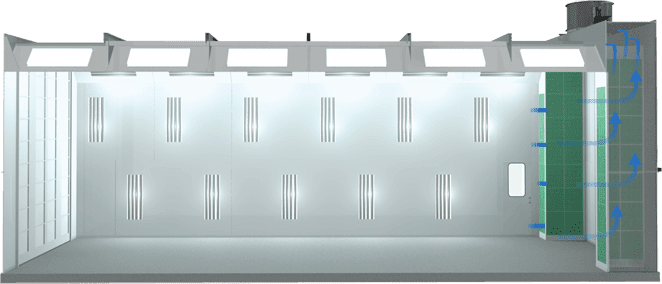

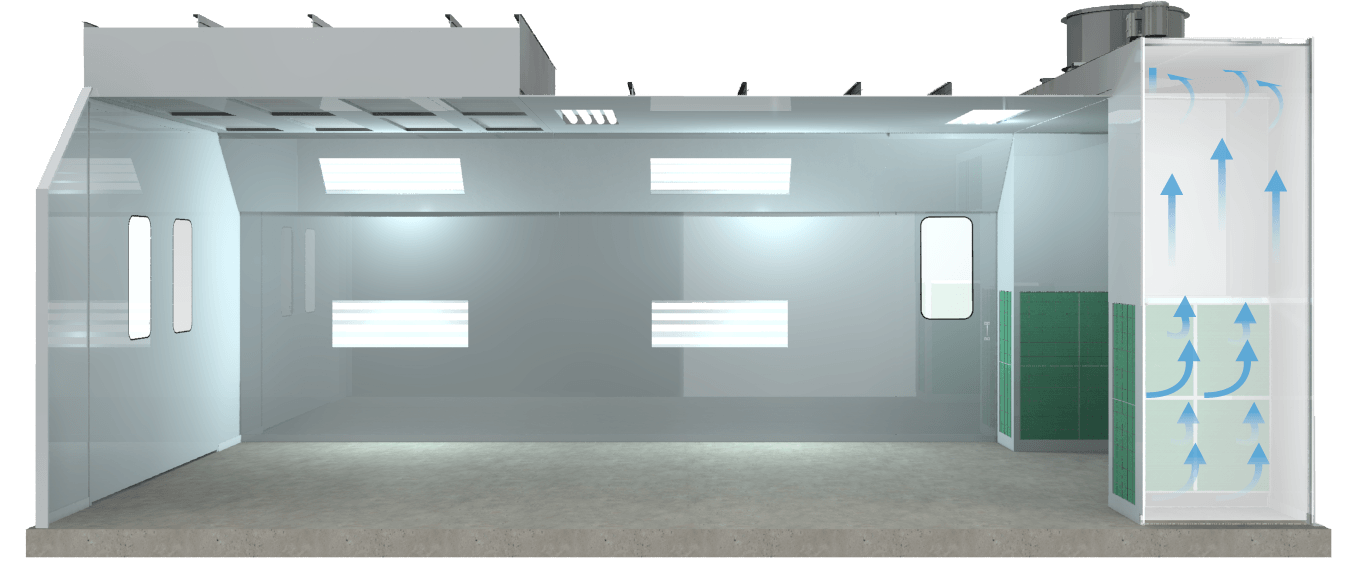

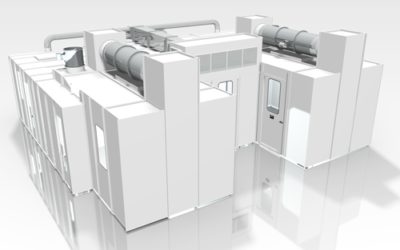

Modified Downdraft Airflow Designs

Recommended for:

Large Equipment and Automotive + High-Quality Finishing Requirements

- Powerful Performance

- Minimal Installation Requirements

- Additional Maintenance and Upkeep

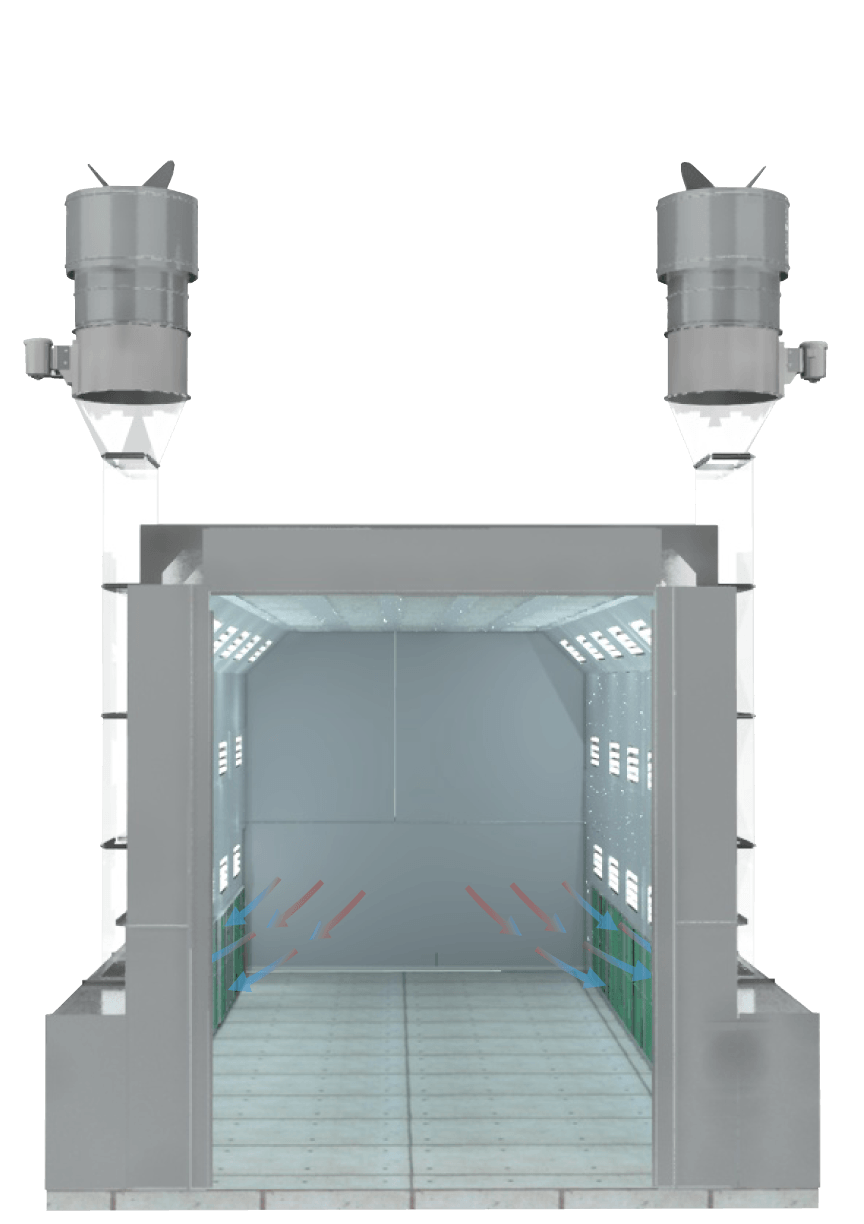

Stage 1

Air is drawn through the top of the booth via a ceiling supply plenum and passes through intake filtration comprised of multiple synthetic layers. This ensures that clean air is introduced into the system while providing uniform airflow throughout the booth.

Stage 2

The air continues down and around the product through precisely balanced airflow, collecting overspray along its path and pushing it away from the spray environment. After reaching the floor, the downdraft airflow is diverted towards side exhaust plenums, which are outfitted with exhaust filters made of continuous glass fiber woven into an open pattern to prevent saturation and poor filtration.

Custom Paint Booth Designs

Mick’s Paint

Spray Systems understood, because of the nature of our business, that our new spray booth required custom considerations. As an educational institution, the booth design and engineering for Dixie Technical College included particularly unique...

Dixie Technical College

Spray Systems understood, because of the nature of our business, that our new spray booth required custom considerations. As an educational institution, the booth design and engineering for Dixie Technical College included particularly unique...

Precision Body & Paint

Precision Body and Paint, a customer in Bend, Oregon, specifically chose Spray Systems to engineer a custom-built spray enclosure that could operate efficiently under the cold conditions of their winters, while still providing a high-end...

Walla Walla Foundry

The Walla Walla Foundry is an internationally known modern contemporary bronze casting facility. The Foundry provides a range of services for producing contemporary sculpture. We’ve completed two booth projects and Spray Systems Inc. provided...

Fender Music Instruments

Fender Music Instruments Corp. selected Spray Systems to design and install a custom paint spray booth for their Robotic Paint Spray system. Because of our reputation throughout the industry, integrators and other booth installers recommend us to...

Puckett Machinery

There are dozens of projects that could illustrate our capability and commitment, but our recent custom installation for Puckett Machinery is a perfect example. As an authorized dealer handling sales, rentals and maintenance of heavy equipment, this...

Amada America

Amada America, a worldwide manufacturer of the finest CNC and heavy equipment machinery chose Spray Systems for their custom paint booth...

Air Tractor, Inc.

Initially, we had planned to upgrade the oldest of nine spray facilities. But we came to appreciate that the better and more cost-effective solution was to create a custom booth to fit the existing infrastructure....