Discover how to get finishes with the highest quality

Large vehicles, today, require finishes that are high tech, and manufacturers of large equipment demand that outcome.

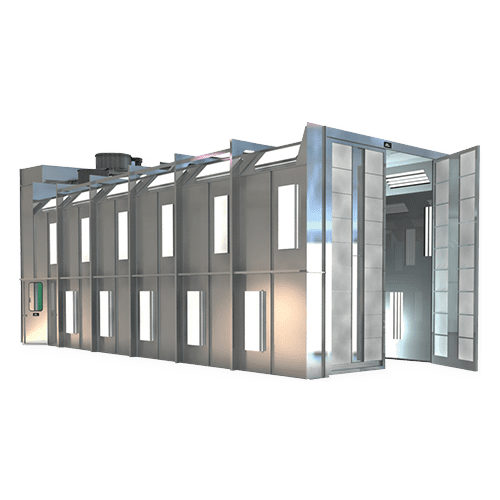

At Spray Systems, we provide our customers with a variety of booth designs, from downdraft, crossdraft, and modified downdraft booths to accommodate any size of truck and large equipment products. Our spray booths for trucks come in widths of include 16, 18, and 20 feet. These truck spray booths can be designed and manufactured in any length necessary to fit the product and the spray systems environment.

Designing and Installing Your Large Equipment Spray Booth to Meet Large Equipment Challenges

Large Equipment spray booths are typically designed with dry filters and sized to accommodate the larger scale products being manufactured, and then painted.

Here are some key questions to answer in designing the right large equipment booth for you:

Size of your product matters and is directly proportional to the size of the spray booth. You will need to consider maintaining at least a 5-foot clearance around the part, and at least 3-foot over the top of the part.

Whether your product is a large truck and trailer, RV, or earth-moving equipment, each needs to be evaluated within the production process to determine what and how the parts are painted during the spray process. The design of a large equipment booth requires that it provide enough part clearance along with ample working area for the painter, which leads to the need to determine the other operational aspects to be designed into the booth.

How big is your facility, and how much area can be dedicated to your spray booth?

Knowing where the booth will be located inside your facility is critical. There are several factors to consider regarding the location of your spray booth:

- Is there enough space above the booth to mount equipment such as an air make-up unit, exhaust fans, and access to lights?

- Are there roof building conditions to consider, such as skylights, utility lines or electrical power service that might be in the way of ductwork or other booth components?

- Will the booth be located adjacent to an exterior wall? If so, can you maintain the required 3-foot clearance from the wall? The booth can be placed adjacent to the wall as long as the wall has at least a (1) hour fire rating.

- Will the booth be located in such a place within the facility that maintains your workflow of a finished product exiting the booth?

Does your spray booth require an Air Makeup Unit (AMU)?

Large equipment booths will require large exhaust volumes. This exhaust air volume must be compensated by some type of air supply system. Typically, a direct gas-fired AMU system replaces the air in the booth that is being exhausted. Remember, the larger the booth, the more air that needs to be supplied. If the booth is improperly designed, the calculated air volume may be too much, or too little, leading to operational inefficiency and poor airflow within the booth. This is also a leading issue in meeting agency guidelines and approvals.

If your booth does require an AMU, where will the AMU be located?

Large equipment booths typically require a large AMU to effectively meet the air flow requirements. Careful consideration must be used to determine the location of these larger AMUs. These units are usually mounted outside the building – horizontally on the roof of the building, or vertically alongside the building. The size and weight of these units need to be taken into consideration based upon the overall size of the booth – some AMUs could exceed 20 feet in length or more.

Can your roof support your AMU and fan equipment?

AMUs can weigh anywhere from 1,200 pounds to 50,000 pounds; can your roof support this weight? If it is not practical to support the unit from the roof, another option is to mount the AMU on a platform inside the building or on top of the booth, itself. When considering an indoor AMU with these designs, you will need to consider adding the required intake duct from the roof line or adjacent wall to the intake of the AMU so as to draw sufficient air from the outside.

Do you need accelerated drying options in the curing process?

Many Large Equipment spray booths that include an AMU (such as the ones we have been describing) can easily add a Bake Mode feature to the booth’s operation. This curing mode is used to accelerate the cure time of the freshly painted product, and therefore, can increase production speed resulting up this accelerated cure time.

The booth’s control panel – which regulates all features of the booth, from lights, to temperature, to air flow – allows you to switch between a spray mode and a bake mode, with temperature control and a bake timer that can be adjusted accordingly based on your curing requirements. The burner, and many of the controls, are already in the AMU unit, so this feature can be added relatively, inexpensively.

Do you need the drive-through to accommodate your production flow?

Many large equipment spray booths are designed with product doors at both ends of the booth. If you require, this booth can be designed to allow the product to enter from one end, and then after painting, can exit the opposite end for you to maintain the product’s production flow inside the facility.

What local and federal regulations do I need to address in the design of the booth?

Large equipment spray booths are highly regulated and are required to meet all the local and federal standards and regulations. These regulations include the following:

- NFPA-33 Spraying of Flammable Material

- NFPA-68 Standards for Explosion Protection

- NFPA-70 National Electric Codes

- NFPA-86 Standards Ovens for Oven and Furnaces

- International Building Codes (IBC)

- International Fire Code (IFC)

- International Mechanical Code ((MC)

- OSHA 1910.107 Protection

- Any other local codes or AHJ (Authority Having Jurisdiction)

All our custom designs will ensure that you achieve the results you need and want from your spray booth solution, and within all local and federally mandated guidelines. And Spray Systems’ custom engineering approach ensures that all requirements to the spray booth are met, as well as safeguarding uniform air flow. The key is to protect the spray environment in such a way as to allow painters to apply finishes with the highest quality which is why we receive so many compliments from our customers, year after year.

Expect Costs of Operating your Spray Booth to go down

By design, all components of our paint booths are rated for high efficiency. From VFD drives and high efficiency motors, to recirculating exhaust systems and advanced LED and T-8 lighting, we provide energy efficient solutions. The result for you: Lower operating costs.

Summing up: Our Large Equipment Spray Booths are Designed for environmental safety and quality

Large Equipment/Truck Booths come with design challenges that must be addressed to ensure you fulfill your finishing objectives while maintaining an environmentally safe operation. This requires that whatever design is customized, that it removes safely and efficiently any overspray from your painting operation. All, while ensuring constant, uniform air flow throughout the work area. The key is that all custom booths meet code and safety requirements NFPA-33 and IFC in order to protect those working in the booth, and those working in the areas outside.