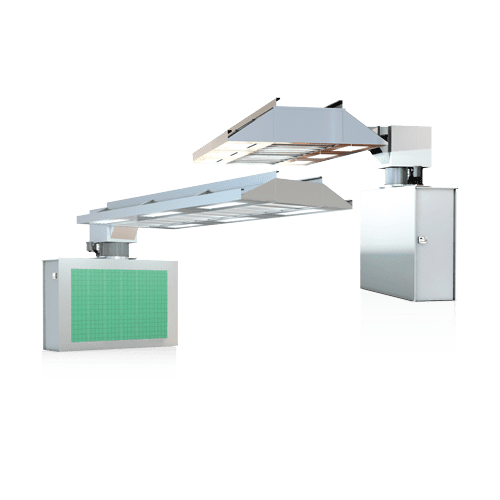

SDP-1 Semi-Downdraft Prep Station draws exhaust air into the filters at the base of the cabinet. This design has the advantage of not requiring a pit, while still having downdraft airflow.

DP-1 Full Downdraft Prep Station better contains all dust particles by using a full downdraft airflow along with gravity by using a below-grade pit design. Customer should consult Spray Systems advisor before they install the exhaust pit.

Package Features & Benefits

- Dual Operating Modes–both semi-downdraft and downdraft prep stations include a dual operating system, allowing to easily switch from prep mode to spray mode controlled from the pneumatic control panel

- CNC and CAD Technology–panels are manufactured of premium 18 gauge G-90 galvanized steel, and are precision-punched on six inch centers, allowing for easy nut and bolt assembly, and exploded view assembly drawings supplied

- Quiet Exhaust Fan–typically operates at low dBa noise levels, below OSHA limits

- High Efficiency Motor–tri voltage, TEFC, motors that match the high efficiency performance of the exhaust fan, three phase with a single phase option

- Exhaust Filters–20” x 25” filters yield a larger filter area, with a specially spun fiber design to remove paint particles efficiently. A manometer to properly manage filter maintenance is included

- Intake Filters–these filters are specifically designed to remove 98% or more of dust particles in order to deliver a Class a finish

- Optional Lighting–high efficiency lighting fixtures designed for mounting outside booth, industrial rated, four-tube (T-8) fluorescent fixtures with dust-tight seals and are ETL listed

- UL Listed–all electrical components and latching devices are UL/ETL listed

- Essential Accessories–all necessary caulking, nuts and bolts, hardware for proper booth installation

Prep stations for automotive paint spray booths can be customized to meet the unique needs of our customers.