Environmentally Safe

Each of our non-recovery spray booths exceeds safety and code requirements – NFPA-33, IFC – to protect those that work in any industrial manufacturing spray environment, while also protecting our atmosphere. Your non-recovery spray booths will be designed to efficiently remove the powder overspray from the painting operation while maintaining uniform air flow throughout the work area.

Flexible and Adaptable

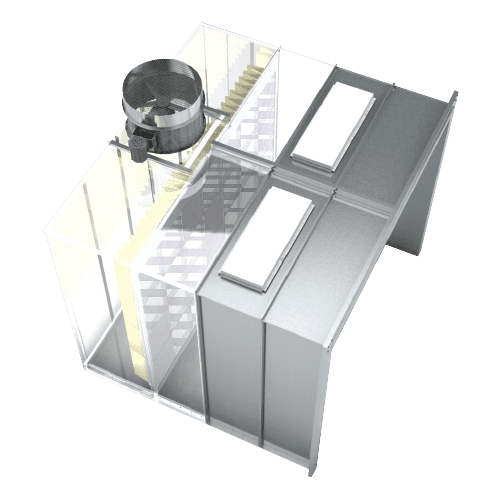

You’ll discover that we custom design our Non-Recovery Powder Booths to be flexible and adaptable to whatever your finishing applications might be. We design open face booths for batch production, as well as high production, conveyorized spray booth models. Adapting front filter doors, air make-up systems and special spray booth controls are just a few ways that we can engineer a custom non-recovery powder booth for you.

Economic and Effective

Our powder coating booths provide you an extremely effective method of powder collecting, at half the cost of a traditional cartridge collector-type powder booth. These powder coating booths are designed with a 3-Stage Filter System that captures the powder overspray, allowing clean air to recirculate back into your plant. This eliminates the need for exhaust stack with expensive air replacement systems. Non-Recovery Powder Booths are ideal for “spray to waste” batch operations.

The 3-Stage Filter System At Work

Stage-1 prefilter pad, an easy-to-replace sacrifice filter that collects most of the powder overspray; Stage-2 pleated filter which protects the more expensive bag filter from finer powder particulates; and Stage-3 a 5-pocket, 12” deep bag filter which prevents fine powder contamination from recirculating in the plant. A pressure switch is included for monitoring the static pressure across the final stage. This pressure switch is a safety device which interlocks with the powder equipment to shut off at a pre-determined set point to warn operators to service the filters.

Appearance and Durability

Your non-recovery powder booth will have a quality appearance with our durable premium grade G-90 galvanized steel–a superior steel material that allows our booths to resist corrosion and to last longer.

Package Features & Benefits

- CNC and CAD Technology – panels are manufactured of premium 18 gauge G-90 galvanized steel, and are precision punched on six inch centers, allowing for easy nut and bolt assembly, and exploded view assembly drawings supplied

- Quiet Exhaust Fan – typically operates at low dBa noise levels, below OSHA limits

- High-Efficiency Motor – tri voltage, TEFC, motors that match the high efficiency performance of the exhaust fan, three phase with a single phase option

- Exhaust Filters – 20” x 25” filters yield a larger filter area, with a specially spun fiber design to remove paint particles efficiently. A manometer to properly manage filter maintenance is included

- Lighting – high efficiency lighting fixtures designed for mounting outside booth, industrial rated, four-tube (T-8) fluorescent fixtures with dust-tight seals and are ETL listed

- UL Listed–all electrical components and latching devices are UL/ETL listed

- Essential Accessories – all necessary caulking, nuts and bolts, and hardware for proper booth installation

Options & Accessories

- Access Doors

- Air Make-up Units

- Air Solenoid Valves

- Constant Velocity Controls

- Control Panels

- Energy savings standby/idle mode

- Exhaust Stack Components

- Front Filter Doors

- Heaters / Infrared

- Lighting

- Magnahelic Gauges

- Observation Windows

- Pressurized Air Supply Plenums

- Safety Shut-Down System

- Specialized Filters