Environmentally Safe

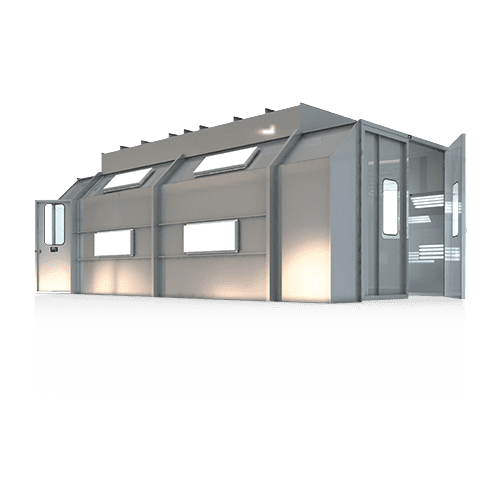

Each of our downdraft spray paint booths meet safety and code requirements –NFPA-33 and IFC –to protect any employees working in the spray area, in addition to the world outside. Your Auto Downdraft Booth can be custom designed to efficiently remove the overspray from the painting operation while maintaining uniform airflow throughout the work area.

Highest Quality Finish

Spray Systems offers three different designs of downdraft spray paint booths: a pit-style downdraft, our modified downdraft, and a semi-downdraft booth which uses the same trustworthy principle with the option of above-ground exhaust filter locations. Our customers frequently compliment our automotive paint booths for creating an environment that allows painters to apply the highest quality automotive finishes.

Lower Operating Costs

We use higher-efficiency components and designs. We offer energy-efficient components from VFD drives, recirculating exhaust systems, high-efficiency motors, (T-8) lighting, and booth idle packages which can result in lower operating costs.

Package Features & Benefits

- CNC and CAD Technology–panels are manufactured of premium 18 gauge G-90 galvanized steel, and are precision punched on six-inch centers, allowing for easy nut and bolt assembly, and exploded view assembly drawings supplied

- High-Efficiency Motor – all motors are energy efficient, totally enclosed, fan cooled, multi-voltage, 208/230/460, three-phase with a single phase option

- Exhaust Filters–20” x 25” filters yield a larger filter area, with a specially spun fiber design to remove paint particles efficiently. A manometer to properly manage the timing of filter change-out

- Intake Filters–these filters, with soft, pliable polyester fibers coated with special adhesives for superior dust collection, are specifically designed to remove 98% or more of dust particles in order to deliver a Class A finish

- Quiet Exhaust Fan–typically operates at low dBa noise levels below OSHA limits

- Lighting–high-efficiency lighting fixtures designed for mounting outside booth, industrial rated, four-tube (T-8) fluorescent fixtures with dust-tight seals and are ETL listed

- Latches–heavy duty, quick release type with positive closing and panic hardware

- Doors/Side Access Door–both the filter and solid type doors have a structural steel tube frame, leak proof wiper type seals at the bottom, and polyfoam seals at the center; the side access door meets NFPA Lifeline 101 requirements, and includes 18” x 36” observation window

- UL Listed–all electrical components and latching devices are UL/ETL listed

- Essential Accessories–all necessary caulking, nuts and bolts, and hardware for proper booth installation

Options & Accessories

- Access Doors

- Air Make-up Units

- Air Solenoid Valves

- Constant Velocity Controls

- Control Panels

- Energy savings standby/idle mode

- Exhaust Stack Components

- Front Filter Doors

- Heaters / Infrared

- Lighting

- Magnahelic Gauges

- Observation Windows

- Pressurized Air Supply Plenums

- Safety Shut-Down System

- Specialized Filters