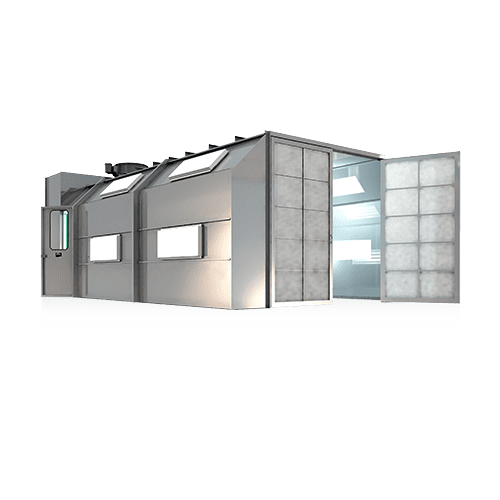

Crossdraft paint booths provide reliable, cost-effective solutions for industrial finishing operations. With horizontal airflow design and proven performance, these spray booths deliver consistent results across a wide range of applications.

CrossDraft vs Downdraft Booth

Understanding airflow patterns is essential when selecting the right paint booth for your operation.

In a crossdraft booth, the air enters and exits horizontally, parallel to the floor. This straightforward design makes crossdraft booths easier to install and maintain.

In a downdraft booth, air enters vertically from the ceiling and exits through the floor grating, pulling overspray directly downward away from the painted surface.

When evaluating paint booth options, consider your specific requirements, including finish quality standards, facility constraints, product dimensions, and budget. Each airflow design offers distinct advantages for different applications.

Discover which configuration best suits your needs in our comparison guide.

Benefits of a Spray Systems Crossdraft Booth

Environmentally Safe

Every Spray Systems crossdraft paint booth meets or exceeds critical safety standards, including NFPA-33 and IFC requirements. Our cross flow paint booth designs protect your workforce while minimizing environmental impact. Custom-engineered airflow systems efficiently capture overspray while maintaining consistent air movement throughout the workspace, ensuring both operator safety and regulatory compliance.

Highest Quality Finish

Spray Systems delivers superior finishing results through three specialized crossdraft spray booth configurations: traditional crossdraft, modified crossdraft with enhanced filtration, and semi-downdraft models featuring flexible exhaust placement. Our automotive and industrial customers consistently achieve exceptional finish quality thanks to optimized airflow patterns that create ideal painting conditions throughout the booth.

Lower Operating Costs

Our energy-efficient crossdraft booth technology helps reduce operational expenses. We integrate cost-saving features, including variable frequency drives (VFD), recirculating air systems, high-efficiency motors, (LED) lighting fixtures, and intelligent idle mode controls. These components work together to minimize energy consumption without compromising performance.

Features

- CNC and CAD Technology: Premium 18-gauge G-90 galvanized steel panel,s precision-punched on six-inch centers, enables straightforward nut-and-bolt assembly with detailed exploded-view drawings included

- High-Efficiency Motors: Energy-efficient, totally enclosed, fan-cooled motors with multi-voltage capability (208/230/460V three-phase, single-phase optional)

- Exhaust Filters: Large-capacity 20″ x 25″ filters with specialized spun-fiber media efficiently capture paint particles; includes a manometer for optimal filter replacement timing

- Quiet Exhaust Fan: Operates well below OSHA noise limits for compliance and improved workplace comfort

- Lighting: External-mount, high-efficiency (LED) fixtures with dust-tight seals, and ETL listing

- Latches: Heavy-duty quick-release design with positive closing mechanism and panic hardware for safety

- Doors/Side Access: Structural steel tube frames with leak-proof wiper seals, polyfoam center seals, NFPA Lifeline 101 compliant side door with 18″ x 36″ observation window

- UL Listed: All electrical components and latching devices carry UL/ETL certification

- Essential Accessories: Complete installation package includes caulking, fasteners, and all necessary hardware for booth installation

Learn More About Crossdraft Booth Design

Options & Accessories

- Access Doors

- Air Make-up Units

- Air Solenoid Valves

- Constant Velocity Controls

- Control Panels

- Energy Savings Standby/Idle Mode

- Exhaust Stack Components

- Front Filter Doors

- Heaters / Infrared

- Lighting Upgrades

- Manometer Gauges

- Observation Windows

- Pressurized Air Supply Plenums

- Safety Shut-Down Systems

- Specialized Filter Media

Code-Compliant Crossdraft Spray Booths

Safety and compliance are fundamental to every Spray Systems cross flow paint booth design.

- NFPA Compliance Standards: Our crossdraft booths incorporate proper ventilation rates, spark-resistant fan construction, integrated fire suppression systems, and additional safety features to ensure full NFPA-33 compliance

- OSHA Requirements: Advanced airflow engineering in our crossdraft spray booth designs maintains air quality within OSHA-mandated exposure limits while protecting operator health

Crossdraft Paint Booth FAQ

What are the main advantages of choosing a crossdraft spray booth over other designs?

Cross flow paint booths offer several key benefits: lower installation costs since they don’t require pit construction, easier maintenance with accessible filters at working height, flexible placement options in existing facilities, and proven reliability for a wide range of coating applications.

While downdraft booths may provide superior overspray control for some high-end finishes, crossdraft booths deliver excellent results for most industrial and automotive painting needs at a more economical price point.

What size crossdraft paint booth do I need for my operation?

Booth sizing depends on your largest product dimensions, production volume, and workflow requirements. As a general rule, allow at least 3-4 feet of clearance on all sides of your largest part for proper air circulation and operator movement. Standard crossdraft booth widths range from 10 to 30 feet, with custom sizes available. Consider future growth needs and whether you’ll be painting single items or batch processing multiple parts simultaneously.

How much airflow is required in a crossdraft spray booth?

OSHA and NFPA standards typically require crossdraft paint booths to maintain an average air velocity of 100 feet per minute (FPM) across the booth’s cross-section. This ensures adequate overspray capture and safe working conditions. The total CFM (cubic feet per minute) needed depends on your booth’s dimensions and is calculated by multiplying the cross-sectional area by 100 fpm. Our engineers can specify the exact airflow requirements for your specific booth configuration and local code requirements.

What maintenance is required for a crossdraft booth?

Regular maintenance keeps your cross flow paint booth operating efficiently and extends equipment life. Key tasks include:

- Replacing intake filters every (500-1000) operating hours (or when pressure drop indicates)

- Changing exhaust filters when manometer readings reach manufacturer limits (typically every 40-80 hours)

- Cleaning booth walls and floors daily to prevent paint buildup

- Inspecting fan belts and motors monthly

- Scheduling annual inspections of electrical components and safety systems.

Proper maintenance ensures consistent finish quality and compliance with safety regulations.

Ready to Install a Code-Compliant Crossdraft Booth?

With decades of experience designing cross flow paint booths, we understand that every operation has unique requirements. We don’t just deliver equipment, we develop comprehensive solutions tailored to your specific needs.

Our Experienced Team combines engineering expertise with practical coating knowledge. Our specialists understand your industry’s challenges and speak your language, ensuring clear communication throughout your project.

Customized Solutions ensure your crossdraft paint booth integrates seamlessly with your operation. From custom dimensions and specialized airflow patterns to equipment integration, we engineer booths that match your exact specifications.

Ongoing Support extends well beyond installation. We provide comprehensive training, process optimization assistance, and long-term technical support to maximize your booth’s performance and longevity.

Request a Quote today to discover how our crossdraft spray booth solutions can enhance your finish quality, reduce operating costs, and improve overall efficiency.