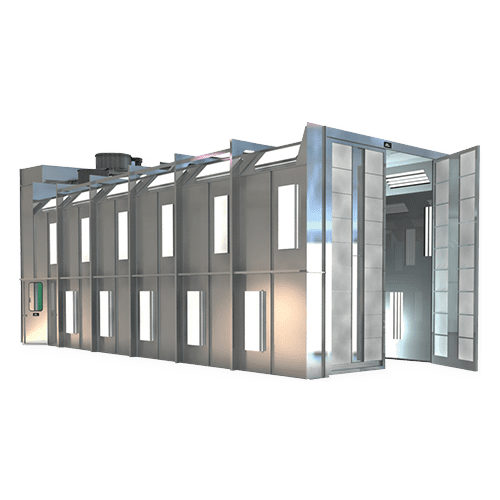

Industrial Spray Paint Booths

We understand that purchasing a custom heavy-duty industrial spray paint booth constitutes a serious investment — one that will affect your workplace in profound ways. That’s why all of our custom heavy-duty industrial paint booths are built with responsible design in mind and are manufactured with the highest quality materials and workmanship to ensure perfect results.

Our custom heavy-duty industrial spray paint booths are great for many industries, run quietly, are built to last, are easy to install, and are all designed in-house to ensure the highest level of quality. With 40 years of experience to back us up, Spray Systems is able to provide maximum flexibility in fabrication, which simplifies field installation while significantly reducing assembly time, effort, and overall expense.

Products

Choosing the Right Booth

Crossdraft vs. Downdraft Paint Booths

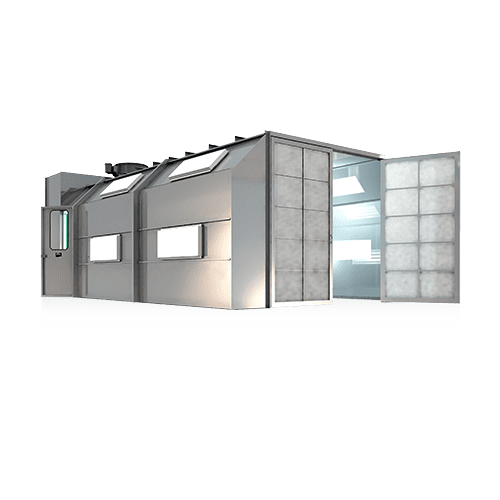

Crossdraft

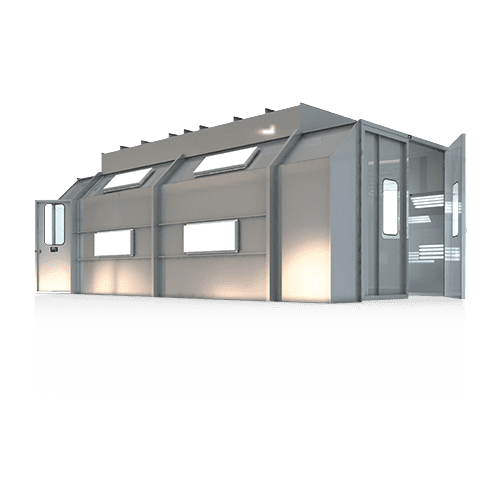

The term “crossdraft” refers to how the air travels through the booth – horizontally along the “cross-section” of the booth. Air passes from the front of the booth (sometimes through supply filters) and then horizontally toward the booth’s rear exhaust chamber. This horizontal flow causes air to uniformly flow over the painted part which provides for a more precise finish.

This crossdraft airflow starts with air entering through the front of the booth where our Spray Systems intake filters are located. As air passes through these filters, dirt and other contaminants that could negatively affect a product’s finish are captured. This particle-free air is the key deliverable for our crossdraft spray paint booth – creating a clean environment for the optimum paint job at the most cost-effective price.

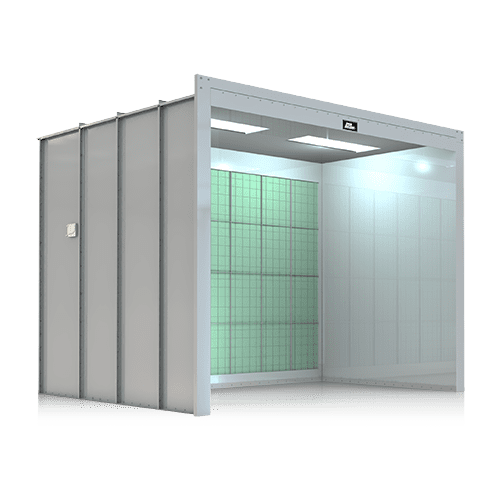

Downdraft

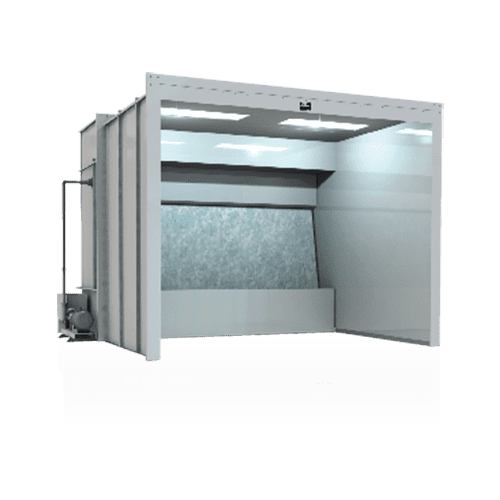

By definition, “downdraft” refers to air travel and its direction within the booth. By design, a downward flow will be maintained starting at the supply filters in the ceiling of the booth down to the floor level. Any overspray that results from the spray activities inside the booth are drawn to the grating over a pit trenched in the floor.

This overspray proceeds through exhaust filters located beneath the grating. As it passes through, the overspray is removed from the air stream and drawn through the exhaust fan and ductwork system – discharging clean air into the atmosphere. Compared to a crossdraft spray paint booth, a downdraft spray paint booth requires more airflow but results in greater control over your finishing environment.

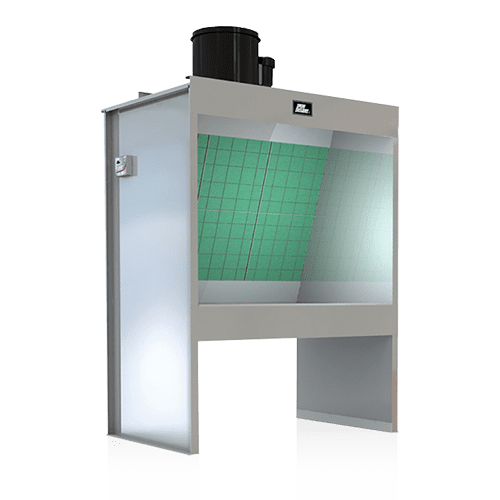

Small Jobs: Bench Spray Paint Booths

Compared to larger models, a bench spray paint booth presents an economical option for smaller spray paint jobs. Open-faced and placed at bench height, operators apply spray paint while standing up. As they work, powerful-but-quiet exhaust systems remove overspray from the painting operation while maintaining uniform air flow throughout the work area.

Dry Filter vs. Water Wash Spray Booths

Dry Filter

Dry filter spray paint booths use layered filters to separate paint particulates from a constant airstream passing through an exhaust filter. There are many types of designs available for dry filter media, dry exhaust filters and even reclaim systems, each of which is ideal for certain volumes and applications.

While dry filtration is a popular choice in most industrial manufacturing sectors, since it can easily accommodate fluctuating demand and changing part sizes, it does require ongoing maintenance. Dry filters get clogged with use and must be routinely replaced to avoid uneven airflow. Despite this, dry filters are ideal for most low-to-medium volume production operations.

Water Wash

Water wash spray paint booths use water as a filtration medium instead of dry filters. Paint overspray is collected and trapped in the water curtain or scrubber section of the washer and then is dropped down into a collection tank. Water wash filtration systems require a higher initial investment than dry filtration, but are ideal for operations that need uniform and consistent airflow.

Due to their durable and efficient design, water filtration systems are perfect for manufacturing processes with an extremely high rate of production, as they can handle significantly more overspray volume compared to dry filters. Additionally, water wash is preferred by many occupational health and building safety codes and is appropriate for spray and finishing compounds of various viscosity and drying speeds.

Read our guide on questions to address when purchasing a spray booth for more guidance.