Spray Booths for Marine Industry

Spray Systems designs and builds custom paint spray booths for marine manufacturers who need safe, code-compliant finishing environments for boats, yachts, hull sections, and large marine components. Marine fabrication requires consistent coating quality, controlled airflow, and equipment that can handle oversized parts. Spray Systems engineers systems that match your specific needs, ensuring your finishing process remains reliable, efficient, and compliant.

Our team has spent decades designing large equipment spray systems for heavy-duty manufacturers. That same engineering approach brings accuracy, airflow control, and environmental consistency to marine operations that coat fiberglass, aluminum, and steel components. If your team needs performance level finishing backed by proven engineering, Spray Systems offers a practical solution.

Marine & Yacht Paint Booth Products

Why Marine Manufacturers Choose Spray Systems

Custom Engineered for Larger Marine Components

Many marine parts exceed the dimensions of standard booths, which is why Spray Systems creates fully custom configurations. Our custom paint spray booths for marine operations can be built as extended-length cross-draft systems, side downdraft systems, or full down-draft enclosures. These designs support hull sections, topside equipment, propulsion housings, decking assemblies, and more.

Consistent Finishing Quality Across Complex Surfaces

Marine coatings need strong adhesion and smooth coverage on curved or contoured surfaces. Proper airflow prevents overspray buildup and supports uniform finishes. Spray Systems balances airflow, filtration, and lighting to help your operators produce clean, even coating results.

Full Compliance With Marine Finishing Requirements

Marine coatings often involve solvent-based or specialty materials that require controlled exhaust, filtration, and airflow patterns. Our custom paint spray booths for marine production meet applicable NFPA, OSHA, and IFC code requirements. Marine operations benefit from predictable compliance without slowing production.

Built for Long-Term Durability in High-Production Environments

Spray Systems utilizes industrial-grade materials and fabrication methods designed for constant use. Booth panels, doors, lighting, and ventilation systems perform reliably in facilities that handle repeated daily coating cycles.

Large Equipment Spray Systems for Boats, Yachts, and Marine Structures

Large-scale finishing is a core specialty at Spray Systems. Marine manufacturers rely on our heavy-duty designs for:

- Hull sections and structural assemblies

- Marine engines and propulsion components

- Cabin modules and superstructure elements

- Masts, towers, and deck hardware

- Fuel tanks and metal fabricated parts

- Fiberglass and composite components

Our custom paint spray booths for marine operations are scalable for everything from mid-sized vessels to oversized assemblies that require expanded height and width clearances. If your production line handles yachts or mega yacht components, Spray Systems can accommodate the size, weight, and airflow demands.

Applications Across the Marine Industry

Metal Fabrication

Coating steel or aluminum is common in shipyards and marine manufacturing. Proper airflow and filtration help maintain smooth finishes on hardware, brackets, frames, and welded assemblies.

Fiberglass and Composite Finishing

Fiberglass hulls and molded components require clean environments to prevent defects. Our systems support gelcoat, primer, and topcoat finishing without contaminants.

Engine and Mechanical Components

Marine engines, outdrives, housings, and pumps require coatings that resist corrosion and saltwater exposure. Adequate airflow supports consistent protection.

Interior Marine Components

Cabin structures, consoles, interior panels, and specialized wood or composite pieces benefit from stable airflow and controlled curing conditions.

How Spray Systems Supports Marine Production

Right-Sized Booth Design

Every marine operation is different. Spray Systems evaluates part dimensions, coating materials, production volume, and available floor space to determine the booth design that fits your workflow.

CAD Driven Engineering

Our engineering team produces detailed CAD layouts and airflow modeling so your booth performs correctly from installation through day-to-day use.

Professional Installation

Spray Systems fabricates and installs each booth with precision. The modular design reduces on-site assembly time and helps marine teams start using their booth without extended downtime.

Reliable Support and Guidance

Marine finishing often involves specialized coatings. Our engineering team helps you select the right airflow pattern, filtration system, air makeup unit, and control package for your operation.

Benefits of Spray Systems Marine Finishing Solutions

- Improved coating consistency across large and complex parts

- Safer, code-compliant finishing operations

- Better control of overspray and particulate buildup

- Efficient airflow distribution throughout the booth

- High-visibility lighting for accurate color application

- Scalable design options for small boats to large yacht components

- Reduced rework and improved coating longevity

Every system is designed to streamline production and support high-quality coating performance.

Get a Custom Quote for Your Marine Spray Booth Project

If your facility needs a dependable finishing solution, Spray Systems can design the right system for your production environment. Let our engineering team review your requirements and build a custom recommendation tailored to your marine or yacht operation.

Contact our spray booth specialists to request a consultation today.

Products

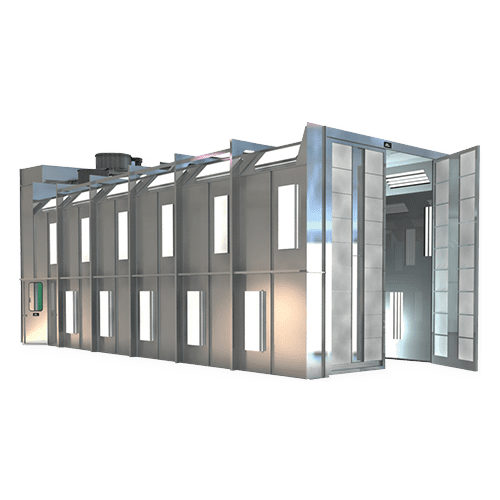

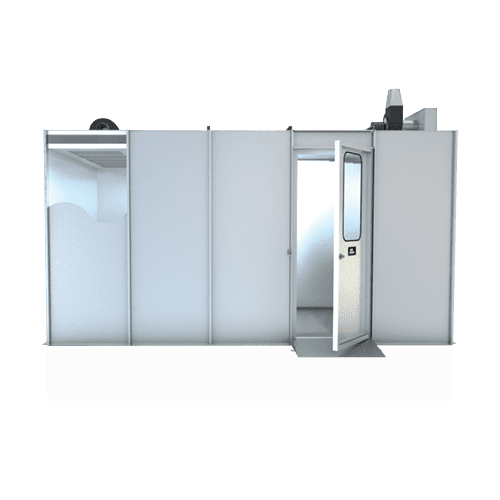

Large Equipment Paint Booth

Our large equipment spray booths are engineered to meet the specific needs of your facility through flexible design. Your large equipment spray booth will be designed to efficiently remove any overspray from your finishing process while ensuring constant, uniform air flow throughout the work area.

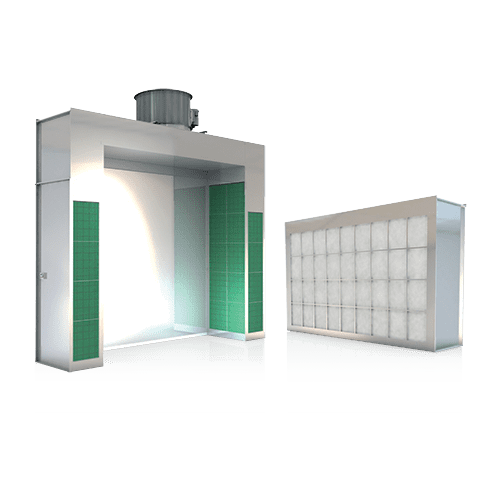

Exhaust & Supply Chambers

An ideal solution for converting an existing area within your facility for spray painting, our exhaust and supply chambers present an economical option for most large equipment manufacturers. Additionally, they also function as great preparation areas for sanding or cleaning parts.

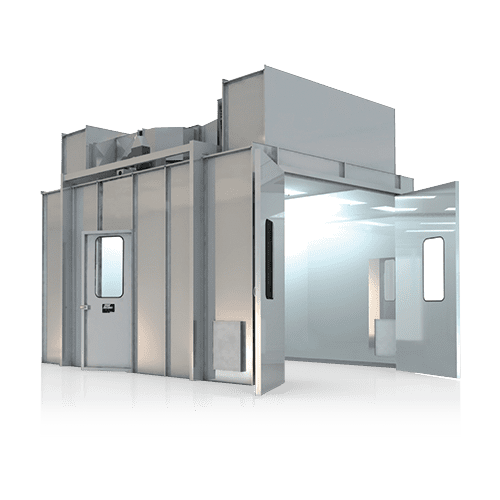

Industrial Drying Enclosures

By accelerating your drying and curing process, our large equipment drying enclosures increase productivity while lowering operating costs. With a wealth of options to ensure the best possible finish, we recommend the use of drying enclosures for both water-borne and solvent-based coatings.

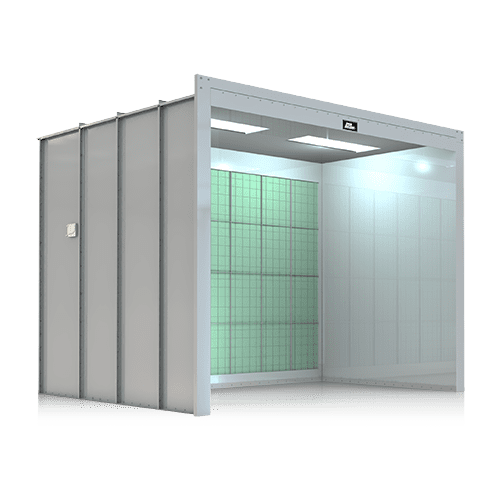

Dry Filter Spray Booths

Using an open-face large equipment spray booth will help save space while efficiently removing particle debris. Our crossdraft dry filter designs ensure the best performance and highest quality finish, making it the perfect fit for any large equipment facility.

Mix Rooms

Engineered to achieve a balanced airflow, our large equipment mix rooms can function as a stand-alone booth or can be affixed to an existing large equipment spray booth. With a comprehensive selection of options, you can give your operator a clean, well-lit and ventilated area for paint preparation.

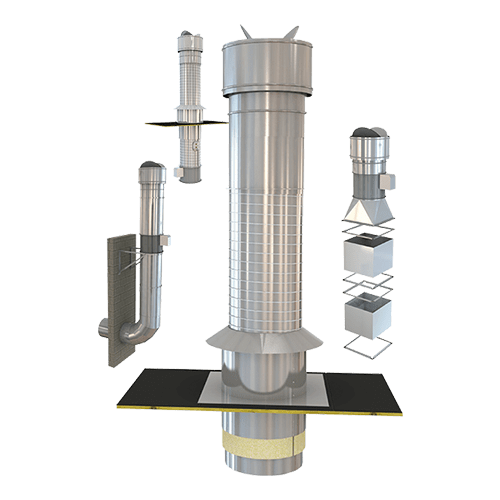

Exhaust Ducts

From flash tunnels to ovens, we provide all of the appropriate components for exhausting spray booths. Along with a comprehensive selection of square, round and spiral configurations, we also provide custom exhaust ducts based on your request.

Have Questions?

Get in touch with a personal Spray Booth Specialist for expert advice and custom solutions that serve your needs.