Read Time: 3m22s

Summary:

- Crossdraft booths have a horizontal airflow that circulates from the front of the booth to the back. They offer lower operating costs, which make them an ideal choice for the automotive industry.

- Downdraft booths originate air from the top of the spray booth and exhaust it through the floor, minimizing the risk of contamination and making for higher-quality finishes.

- Air makeup units can be installed to maintain the pressure inside your spray booth in the event that air is not replenished at the rate that it is exhausted.

- Choosing the right airflow system depends largely on your booth’s filtration needs and your overall production needs.

Airflow characteristics are a defining element of any spray booth design, so it’s one of the first things finishing operators need to consider when upgrading to a new booth. While there are only a handful of options when selecting a type of booth, each one carries a unique set of advantages and possible drawbacks. Airflow systems impact every aspect of a booth’s operations, so companies need to consider how their chosen design effects operating costs, quality of results and workplace safety.

Crossdraft Booths

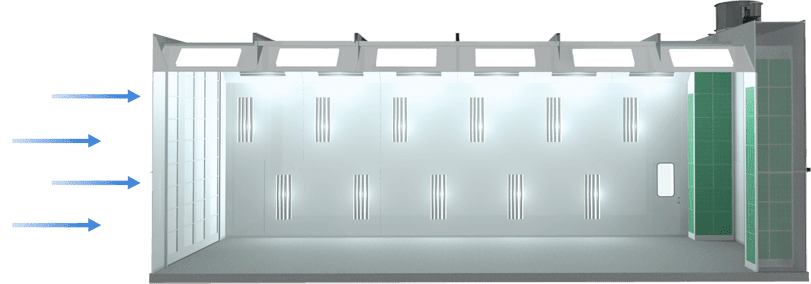

Crossdraft booths are often a common choice for relatively basic applications. These designs are characterized by horizontal airflow that originates from the front of the booth and exhausts through the rear. While this allows for flexibility in part sizes and relatively low operating costs, the direction of airflow can increase the risk of flaws and contamination that could compromise the coating quality. Since air is drawn from the front to the back, there is also a risk of the uneven application over time due to overspray.

Downdraft Designs

Downdraft booths are defined by vertical airflow that originates from the top of the booth and exhausts through the floor. Vertical flow is preferable for quality-oriented applications since it minimizes contamination from debris and overspray compared to horizontal. However, manufacturers also have to consider the higher cost of installation, maintenance requirements and demands on the facility.

Modified Downdraft

Modified downdraft booths conduct air from the top of the booth to exhaust vents that run along its base. This creates a near-vertical airflow that offers similar protection from contamination while mitigating some of the drawbacks associated with conventional designs. However, these booths can be maintenance-intensive due to extra ductwork and can require additional safety measures than a standard design would.

Semi-Downdraft

Airflow in a semi-downdraft booth is a true combination of horizontal and vertical. Flow originates from the ceiling of the booth, usually from a supply unit located near the front. The air passes diagonally downwards, is drawn across and exits the booth through the base of the walls or rear. While specific conditions vary, this type of flow is ideal for operators who want to strike a balance between efficiency, speed, and quality.

Other Airflow Considerations

Filtration

The next step after choosing an airflow design is to accommodate the filtration needs of the booth, and whether a recirculation system is a good fit. Filtration is a crucial component in the design in order to ensure employee safety while meeting all regulation codes, including those set forth by the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Agency (NFPA). When in doubt, you should always consult with a Spray Systems expert about how we can satisfy local and national regulations in your booth design while meeting your production needs.

Recirculation

Recirculation features are an option for booths of any airflow design. There are several ways to recycle air and spray compounds through a recirculation filtration system. These systems can help drive down operating costs and reduce waste, but owners also need to consider their potential impact on regulatory compliance and worker safety. It’s also important to determine what percentage of exhaust removal is required for your booth. Recirculation systems are not as efficient for larger booths that require stricter humidity and temperature controls.

Air Make-Up Units

Since booths are typically sealed environments, they can develop higher or lower air pressure than space outside. If air is exhausted from the booth faster than it’s replaced, then it can hinder your operations and increase the risk of contaminants getting inside. In these cases, booths can be equipped with make-up units that maintain positive interior pressure, which helps keep the unit cleaner and safer.

Going with the Right Flow

Every major decision regarding the design of your spray booth can be complicated. At Spray Systems, our experienced team of engineers works closely with our customers to help them understand the key factors to consider when making design selections that fit their needs. We leverage our airflow expertise to build custom solutions that promote efficiency, safety, and long-lasting value. For advice, questions or to request a custom quote, contact our trusted advisers today!