Custom Automotive Paint Booths Built Around Your Process

Empowering Automotive Production

Precision, reliability, and repeatable quality—that’s what your team needs from every coat of paint. At Spray Systems, we build automotive paint booths designed specifically for your workflow, your compliance needs, and the vehicles or parts you paint. From high-production automotive finishers to specialty body shops, our booths are engineered to help you deliver flawless finishes safely and efficiently.

We don’t offer one-size-fits-all spray enclosures. Instead, we collaborate with your team to understand your production goals, equipment layout, finishing needs, and compliance requirements. Our custom-built automotive spray booths are designed to meet NFPA 33 Standards and help you maintain a clean, controlled environment that protects both your operators and your product quality.

Automotive Paint Booth Products

Engineered for Automotive Manufacturing & Collision Repair

Your paint process is a critical part of your operation. That’s why our booths are purpose-built for automotive use cases, offering the durability, airflow control, and visibility your team needs to get consistent results.

Some of the most common automotive applications we support include:

- Full vehicle finishing lines for OEMs and tier suppliers

- Large equipment spray booths for buses, trucks, and heavy-duty fleet vehicles

- Prep and paint booths for collision centers and body shops

- Powder coating booths for components and frame parts

- Bench booths for smaller repair work or specialty parts painting

No matter the size or complexity of your operation, our team can design a solution that fits your space, supports your schedule, and scales with your business.

Why Automotive Manufacturers Choose Spray Systems

We’ve spent more than four decades helping automotive companies improve paint quality, reduce downtime, and stay compliant with national safety standards. You can expect your booth to do more than meet basic specs; it will be built to help you meet your production goals day after day.

Our customers appreciate:

- Customized airflow systems to improve overspray capture and better finishes

- Advanced filtration and exhaust design to protect your operators and environment

- LED lighting for better light uniformity and improved visual acuity throughout the spray booth environment

- Support from design through installation with a team that knows your industry

- NFPA 33-Compliant construction for safety and booth code adherence

Every booth we build is the result of direct input from manufacturers, body shop owners, and facility managers who rely on dependable, high-performance spray environments.

Your Process. Our Priority.

When you work with Spray Systems, you’re not just buying a spray booth; you’re getting a dedicated team that’s here to help make your job easier. We ask the right questions, listen to your needs, and deliver a solution that fits your production floor and supports your operators.

If you’re planning a new paint line or looking to upgrade an outdated booth, we’re here to help you build the right system for your goals.

Talk to an Automotive Spray Booth Expert

Ready to start the conversation? Our team is here to answer questions, provide specs, and guide you through the planning and installation process. Reach out today to learn how a custom automotive paint booth from Spray Systems can improve your finish quality, safety, and throughput.

Automotive Spray Booth Case Studies

Precision Body & Paint

Precision Body & Paint, based in Oregon, chose Spray Systems to engineer a custom-built paint booth enclosure that could operate efficiently under the cold conditions of their winters while still providing a high-end finish. Spray Systems designed and manufactured the automotive paint booth to be easily maintained under heavy production requirements and incorporated special lighting which allowed operators to produce unique high-quality finishes.

Dixie Technical College

Dixie Technical College, an educational facility based in Utah, selected Spray Systems to design a custom automotive paint booth that could serve as an instructional device. To accommodate their requirements, Spray Systems had to safely incorporate additional glass into the booth design which would allow students to observe the technician and instructor working inside. Additionally, the state-of-the-art paint booth needed to be a bit larger than typical for a 30-foot drive-through downdraft design so that students could work on larger vehicles.

Products

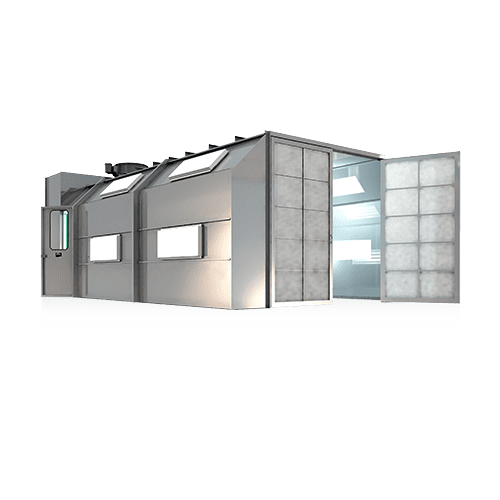

Crossdraft Paint Booths

We provide custom automotive spray booth designs to meet the unique needs of your facility. Whether you need a front flow, rear flow or twin tower style spray booth, our crossdraft airflow designs will ensure uniform balance of air ventilation for increased efficiency.

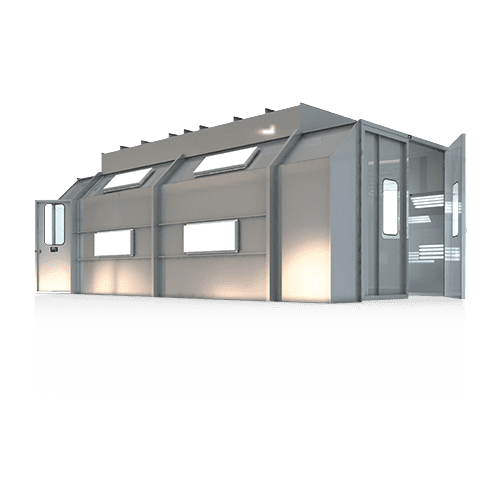

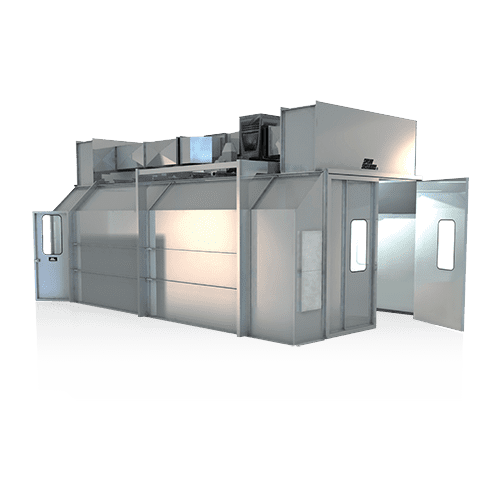

Downdraft Paint Booths

Spray Systems offers three different designs of automotive downdraft booths: a pit-style downdraft, a modified downdraft and a semi-downdraft booth which uses the same trustworthy airflow principle with the added option of above-ground exhaust filters.

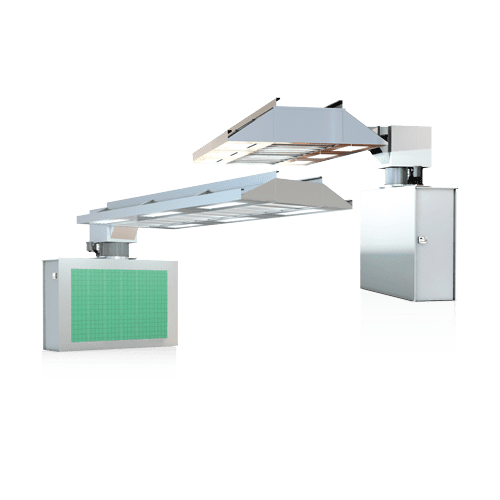

Exhaust & Supply Chambers

Our exhaust and supply chambers are perfect for transforming your facility’s existing areas for spray painting. Additionally, their modular design provides the added flexibility of functioning as a preparation area for sanding or cleaning parts prior to finishing.

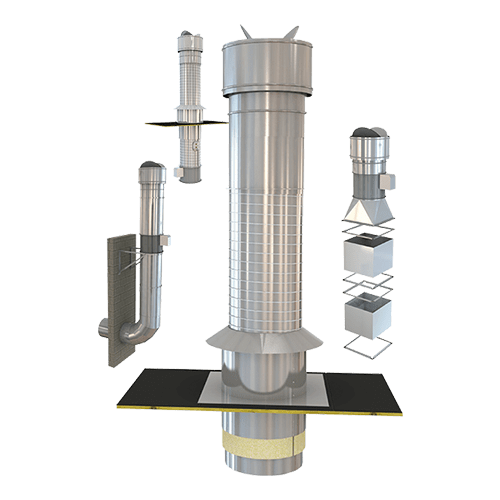

Exhaust Ducts

We offer all of the required components for sufficiently exhausting your paint booths, including exhaust ducts, flash tunnels and ovens. Along with a comprehensive selection of spiral, round and square exhaust configurations, we also provide custom solutions based on your request.

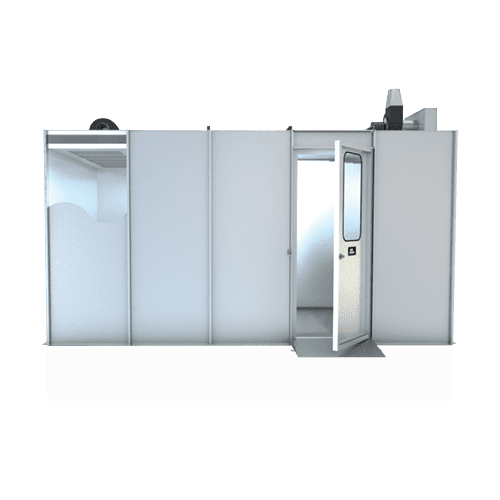

Mix Rooms

Give your operator a clean, well-lit and ventilated area for preparing and mixing the perfect color match with our flexible automotive mix rooms. Designed to achieve a perfectly balanced airflow, your paint mix room can function stand-alone or fixed to an existing automotive paint booth.

Paint Drying Rooms

Accelerate your drying process of water-borne and solvent-based paints by using our auto dry room. Designed to provide optimum curing time, our drying rooms can be outfitted with a number of options to improve efficiency even further, including infrared sensors and sophisticated fan systems.

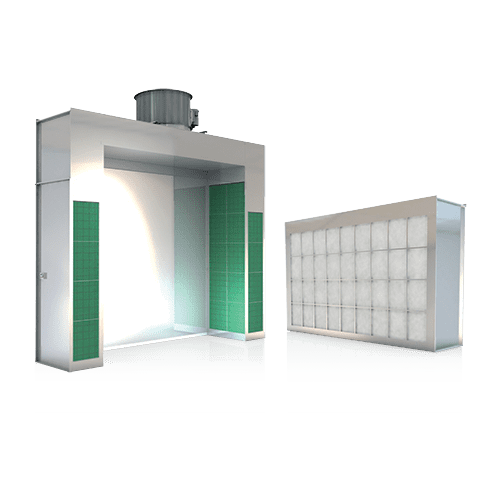

Semi Downdraft Prep Stations

Our automotive prep stations help mitigate paint contamination via high-efficiency motors and whisper-quiet exhaust fans. To accommodate your unique finishing production process, we offer two effective prep station designs: a semi-downdraft and full-downdraft ventilation model.

Have Questions?

Get in touch with a personal Spray Booth Specialist for expert advice and custom solutions that serve your needs.