Custom Paint Spray Booths for Large Equipment

The Right Tools

Designing a custom large equipment paint spray booth presents some unique challenges. Namely, it has to be big enough to accommodate a range of products without affecting the rate-of-production. A poorly-designed paint booth can present a myriad of problems that can have far reaching consequences on production performance, which is why it’s important to design a booth around your facility’s unique manufacturing process.

Over our 40 years of experience, we’ve witnessed the impact of our designs on countless production lines. A well-engineered large equipment paint booth empowers operators to excel at their job and enables managers to add value to their production process through increased efficiencies. There’s a common saying in our industry, “a man is only as good as his tools,” and we couldn’t agree more.

Large Equipment Paint Booth Products

Built for the Challenge

Strong Products for Heavy Equipment

Industry Leading Safety Standards

Products

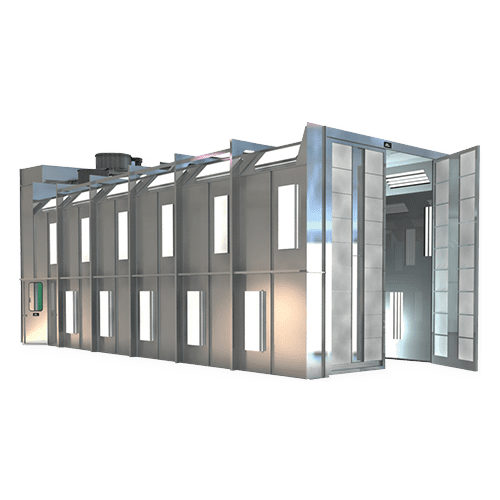

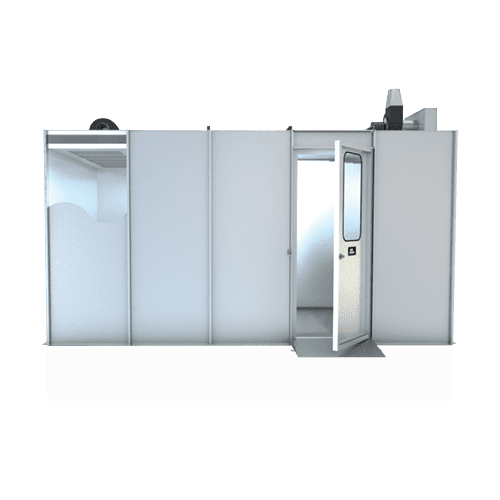

Large Equipment Spray Booths

Our large equipment spray booths are engineered to meet the specific needs of your facility through flexible design. Your large equipment spray booth will be designed to efficiently remove any overspray from your finishing process while ensuring constant, uniform air flow throughout the work area.

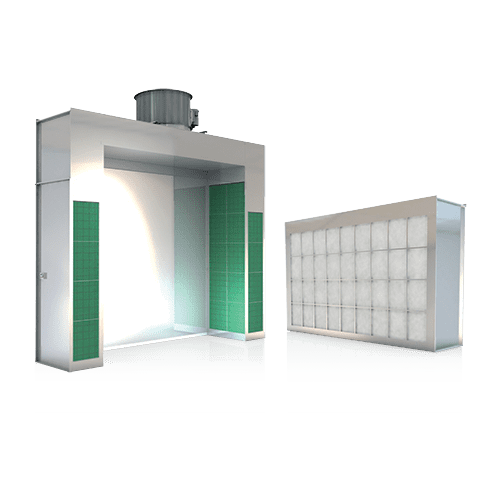

Exhaust & Supply Chambers

An ideal solution for converting an existing area within your facility for spray painting, our exhaust and supply chambers present an economical option for most large equipment manufacturers. Additionally, they also function as great preparation areas for sanding or cleaning parts.

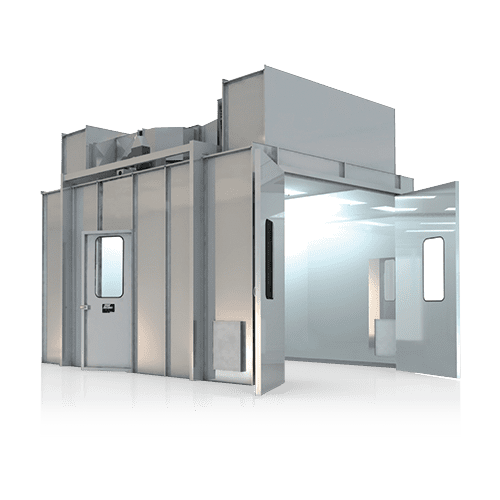

Industrial Drying Enclosures

By accelerating your drying and curing process, our large equipment drying enclosures increase productivity while lowering operating costs. With a wealth of options to ensure the best possible finish, we recommend the use of drying enclosures for both water-borne and solvent-based coatings.

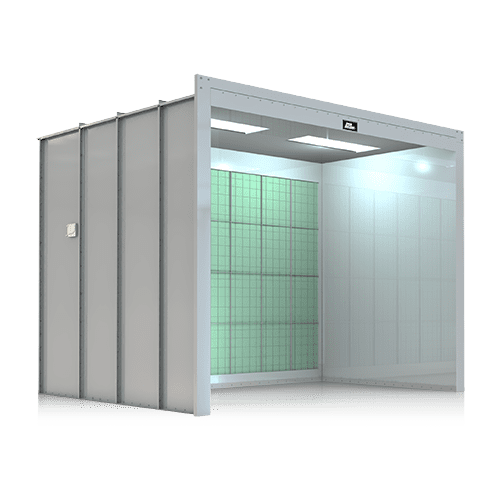

Dry Filter Spray Booths

Using an open-face large equipment spray booth will help save space while efficiently removing particle debris. Our crossdraft dry filter designs ensure the best performance and highest quality finish, making it the perfect fit for any large equipment facility.

Mix Rooms

Engineered to achieve a balanced airflow, our large equipment mix rooms can function as a stand-alone booth or can be affixed to an existing large equipment spray booth. With a comprehensive selection of options, you can give your operator a clean, well-lit and ventilated area for paint preparation.

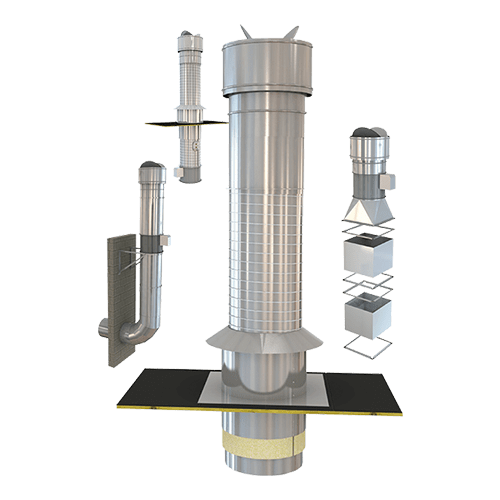

Exhaust Ducts

From flash tunnels to ovens, we provide all of the appropriate components for exhausting spray booths. Along with a comprehensive selection of square, round and spiral configurations, we also provide custom exhaust ducts based on your request.

Custom Large Equipment Paint Booths

Amada America

Amada America, a worldwide manufacturer of CNC and heavy equipment machinery, chose Spray Systems for our renowned large equipment paint booth designs. We were able to assist Amada by creating a large spray booth facility which could easily accommodate a wide variety of machinery sizes. Our heavy-duty designs and thoughtful engineering provided them with a tough booth that could withstand difficult operating conditions.

Puckett Machinery

Puckett Machinery, an authorized Caterpillar dealer based in Mississippi, contacted Spray Systems to assist in upgrading their aging facility with a custom large equipment paint booth. Spray Systems was tasked with designing a crossdraft booth into a tight 60-by-20-by-20-foot area. Despite the spatial limitations, our large equipment paint booth was able to easily fit heavy equipment, vehicles and tools used in construction and terrain management.

Our Large Equipment Customers

Have Questions?

Get in touch with a personal Spray Booth Specialist for expert advice and custom solutions that serve your needs.